Before connecting air

motor to air line

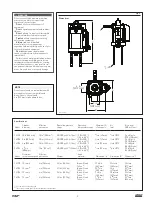

Lincoln series III air motors are fully

pneumatic and require minimum specified

size of air supply hose for proper operation

Check specifications for minimum ID of air

supply hose, corresponding sizes of air

controls and accessories that allow

nonrestrictive air flow Lincoln filter,

regulator with gauge and lubricators are

available as combination units (FRL)

It is recommended to use a 40 micron

minimum pneumatic filter and pressure

regulator with this system

Special lubricant is used in assembly of air

motors It is not recommended to lubricate

system after it has been installed New

lubricant will wash away factory lubricant

and may result in air motor failing Added

lubrication could also result in critical small

pneumatic paths being blocked resulting in

malfunction

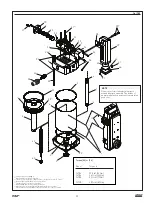

For

1

/

2

in

(13 mm)

air line -

Model 85387-8

For

3

/

4

in

(19 mm)

air line -

Model 85387-12

If quick disconnect coupling should be

used, install supplied coupler to ensure

proper air motor operation

Operating precautions

Use Lincoln replacement parts to assure

compatible pressure rating

Heed all warnings

Do not operate air motor in excess of

recommended pressure range

Disconnect air line and relieve (vent)

pressure before servicing and when idling air

motor for long periods of time

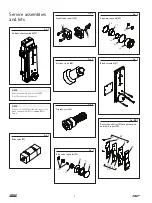

Service and

disassembly

procedure

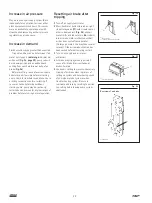

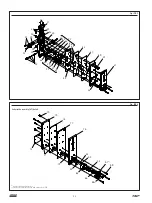

Attach air motor to

pump tube

1

Tightly attach tie rods (

41

) to air motor

lower casting Use short threaded end of

tie rods

2

Mount air motor to top of pump tube

outlet and tightly connect coupling nut to

air motor piston rod (

5, 36

and

72

)

3

Attach tie rods to pump tube with four

nuts (

42

) Leave nuts loose

4

Connect air supply

5

Slowly cycle pump several times using

only enough air pressure to operate pump

without pump stalling

6

Stop pump on

up

stroke and tighten four

nuts (

42

) to securely fasten air motor to

pump tube

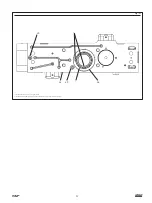

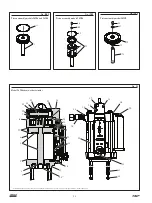

Modular design of air motor and accessibility

of vital operation parts make service

available without taking air motor out of line

or without complete disassembly

Power valve

1

Remove four screws (

27

and

34

)

2

Remove end caps (

10

and

14

)

3

Push out valve spool (

13

)

4

Remove spool bumpers (

9

)

5

Remove o-ring (

11

)

6

Remove four screws (

37

) and lift

valve body (

12

)

7

Remove gasket (

15

) to complete valve

disassembly

8

To reassemble, reverse procedure

WARNING

Do not

alter or modify any part of equip-

ment

Always

check equipment for proper

operation before each use Verify safety

devices are in place and operating properly

Failure to comply

may result in death or

serious injury

NOTE

Ground air motor according to local codes

when flammable materials are pumped

WARNING

Always disconnect air supply and relieve

pressure before checking, servicing or repair-

ing any part of air motor

Failure to comply may result in death or

serious injury

WARNING

Never

exceed maximum air or fluid working

pressure of lowest rated system component

Failure to comply may result in serious

bodily injury and/or property damage

WARNING

Always read and follow fluid and solvent

manufacturer’s recommendations in regards

to use of protective clothing and equipment

Failure to comply

may result in death or

serious injury

6