3. Design and function

page 12

EN

3. Design and function

3.1 General information

Oil + air lubrication systems are total-loss oil

lubrication systems which are used in centralized

lubrication to provide minimal quantity metering of

oils. Oil + air lubrication systems are employed in a

wide range of applications. Typical fields of applica-

tion for oil + air lubrication systems are:

)

Rolling bearing lubrication

)

Linear guide lubrication

)

Chain lubrication

)

Rack and pinion lubrication

)

Lubrication for cutting and non-cutting shap-

ing

)

Installation and process oiling

3.2 Principle of oil + air lubrication

In oil + air lubrication, a continuous stream of air

(compressed air) separates a volumetrically me-

tered quantity of oil into a streak in a lubrication

line and transports it along the pipe wall to the

lubrication point. Metering can be performed by

piston distributor, injection oiler, micropump, an oil

+ air metering unit, etc.

The volumetrically metered quantity of oil is fed

into the air stream in bursts and is transported by

the air stream to the attached lubrication point

line. A nearly continuous oil flow is generated by a

lubrication point line that is at least 1 m long

between the metering device and the entrance to

the lubrication point. This oil flow exits the lubrica-

tion point line as fine oil droplets and is fed to the

lubrication point. The oil droplets fed to the lubri-

cation point lubricate the friction partners, while

the compressed air is discharged into the sur-

roundings nearly free of oil.

3.3 Fields of application

Oil + air lubrication systems provide a continuous,

finely metered flow of oil which can be tailored to

different operating conditions by selecting the

metered quantity, setting the velocity of com-

pressed air stream and changing the lubricating

cycle sequence. An excellent use of oil + air lubri-

cation is the lubrication of high-speed rolling

bearings, for example in spindles for machine tools.

Other applications include the lubrication of high-

speed transport chain conveyors that do not sup-

port intermittent lubricant feeding due to their high

rotating speed. In production processes for textile

fibers, an oil + air lubrication system can be used to

apply minimal quantities of lubricant (gripper

lubrication).

Summary of Contents for OLA Series

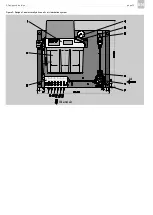

Page 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Page 49: ...blank page ...

Page 50: ...blank page ...

Page 51: ...blank page ...