3. Design and function

page 14

EN

3.5 Description of components

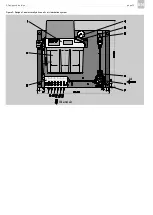

Figure 1 shows an oil + air lubrication system;

Figures 2 and 3 show the various oil + air metering

units. Figure 4 shows the hydraulic diagram of an

oil + air lubrication system.

Compact unit without control unit (1)

The compact unit without control unit (1) consists

of a gear pump, lubricant reservoir (2), the valve

set required for pressure relief and regulation, a

pressure switch for electrical monitoring of oil

pressure build-up in the main lubricant line, a

pressure gauge (4) for visual monitoring of oil

pressure build-up in the main lubricant line, and a

fill level switch for fill level monitoring.

Compact units are available in model designs with

or without a control unit. In the model design

without a control unit, the compact unit (and

thereby the lubrication interval) is controlled by the

control unit of the machine that the oil + air lubri-

cation system is mounted on. In the model design

with a control unit, the compact unit is equipped

with an electronic control unit that controls the

compact unit (and thereby the lubrication interval).

Details on the function and operation of the com-

pact unit and the electronic control unit can be

found in the assembly instructions for the compact

unit and the operating instructions for the elec-

tronic control unit which are included in the scope

of delivery of the oil + air lubrication system.

Compressed air control valve (6)

The compressed air control valve (6) is used to set

the air pressure of the compressed air fed to the oil

+ air metering unit and the lubrication point lines.

The compressed air transports the oil streak on the

inner wall of the lubrication point line, starting

from the oil + air metering unit, through the lubri-

cation point line and to the lubrication point. The

compressed air must be fed uniformly to ensure

constant transport of the oil streak, which ensures

constant lubricant supply to the lubrication point.

The air pressure is set manually and can be read

directly on the integrated pressure gauge (7) on

the compressed air control valve (6). An air filter

with an integrated water separator can optionally

be used.

Figure 1. Design of an electrically driven oil +

air lubrication system (schematic diagram,

subject to change)

1 Compact unit without control unit

2 Lubricant reservoir

3 Filler socket

4 Oil pressure gauge

5 Compressed air connection

6 Compressed air control valve

7 Pressure gauge for compressed air supply

8 Pressure switch for minimum air pressure

9 Oil + air metering unit

Summary of Contents for OLA Series

Page 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Page 49: ...blank page ...

Page 50: ...blank page ...

Page 51: ...blank page ...