4. Installation instructions

page 23

EN

Installation holes for the attachment of the oil + air

lubrication system to the wall must be made in

accordance with the stipulations of the section

'Mounting dimensions'.

Caution!

During installation work - and particu-

larly when drilling - the following points

must be observed:

)

Existing supply lines must not be

damaged by the installation work.

)

Other units must not be damaged

by the installation work.

)

The oil + air lubrication system

must not be mounted within the

radius of activity of moving parts so

it will not interfere with or be stuck

by moving parts.

)

The oil + air lubrication system

must be installed a sufficient dis-

tance away from sources of heat,

so that the maximum ambient

temperature of 40°C is not ex-

ceeded.

)

Country specific installation and

accident prevention regulations

must be observed.

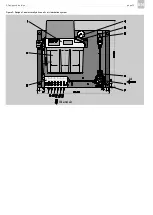

4.2 Mounting dimensions

Oil + air lubrication systems are intended for wall

mounting. They are attached to the intended

mounting location using appropriate fastening

materials (e.g., bolts, washers, and nuts).

For the dimensions and location of the fixing holes,

see the documentation of the oil + air lubrication

system. If no documentation is available, the di-

mensions and location of the fixing holes for

mounting the unit can be determined by taking

measurements.

If no documentation is available, you can

directly request the documentation from

SKF Lubrication Systems Germany

GmbH.

4.3 Electrical connection

4.3.1 Electrical connection motor

In the standard design, oil + air lubrication systems

contain compact units. Compact units are driven by

electric motors. The electric motors are capacitor

motors designed for 115 / 230 V 50 / 60 Hz

single-phase alternating current.

Danger!

Electrical connections for the compact

unit may only be established by qualified

and trained personnel authorized to do

so by the operator. The local conditions

for connections and local regulations

(e.g., DIN, VDE) must be strictly ob-

served. Significant bodily injury and

property damage may result from an

improperly connected compact unit.

In the basic oil + air lubrication system design

without a control unit, the electrical connection to

the motor is established using a rectangular con-

nector as per DIN EN 175301-803-A (clamping

range Ø 8 - 10 mm). In the basic design with a

control unit, the motor is connected to the elec-

tronic control unit.

Summary of Contents for OLA Series

Page 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Page 49: ...blank page ...

Page 50: ...blank page ...

Page 51: ...blank page ...