4. Installation instructions

page 25

EN

4.4 Control and monitoring

Oil + air lubrication systems are available in de-

signs with and without control units. The latter do

not contain an electronic control unit. This type of

oil + air lubrication system is controlled and moni-

tored by the control unit of the machine that the

system is mounted on. An oil + air lubrication

system with a control unit contains an electronic

control unit that is integrated into the compact unit

and controls and monitors the system.

4.4.1 Oil + air lubrication systems

without control unit

Oil + air lubrication systems without an integrated

electronic control unit are controlled by the control

unit of the machine that the system is connected

to. The machine control unit controls the pump's

cycle time and delay time and the compact unit's

interval time in accordance with the amount of

lubricant required by the lubrication points. The

pump cycle time is the duration from when the

gear pump motor is switched on until the maxi-

mum oil pressure is reached in the main lubricant

line, which is monitored by a pressure switch. This

period is also referred to as the monitoring time.

The pump delay time is a period during which the

gear pump motor continues to run after the maxi-

mum oil pressure is reached in the main lubricant

line. This period ensures that the metering cham-

bers in the oil + air metering unit are completely

emptied. The pump cycle and delay time is also

referred to as the contact time. The interval time is

the period between two contact times. A lubricating

cycle consists of the contact time and the interval

time.

Operating mode S3 for the gear pump motor is

used to define the interval time and the gear

pump's cycle time and delay time. Consult the

documentation of the oil + air lubrication system

for information about this operating mode.

The following are monitored:

)

Pressure build-up in the main lubricant line

(oil pressure build-up)

)

Minimum air pressure of the compressed air

supply

)

Fill level in the lubricant reservoir

With regard to monitoring pressure build-up in the

main lubricant line during a lubricating cycle, note

that several seconds may pass after the gear pump

motor is switched on before the oil pressure switch

responds. A fixed monitoring time for oil pressure

build-up is recommended so that the machine

control unit waits until this time has elapsed to

issue a fault notification if the required oil pressure

is not reached. A period of approx. 60 seconds is

recommended.

The oil pressure switch responds once the required

oil pressure has been reached.

If the required oil pressure is not reached, the

machine must be shut down to prevent underlu-

brication of the bearings.

In order to prevent underlubrication of the bear-

ings, monitoring of the minimum air pressure of

the compressed air supply must be configured in

such a way that the machine is shut down if the

required pressure is not reached or the pressure

drops excessively. Ensure that a time buffer is

stored in the machine control unit to level out brief

pressure fluctuations in the compressed air supply.

In order to prevent underlubrication of the bear-

ings, monitoring of the minimum fill level of the

lubricant reservoir must be configured in such a

way that the machine is shut down if the fill level is

too low.

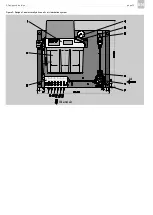

Summary of Contents for OLA Series

Page 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Page 49: ...blank page ...

Page 50: ...blank page ...

Page 51: ...blank page ...