4. Installation instructions

page 27

EN

4.5 Compressed air line connection

The compressed air line must be connected to the

oil + air lubrication system in such a way that no

forces can be transferred to the assembled oil + air

lubrication system (stress-free connection).

Danger!

Before connecting the oil + air lubrica-

tion system to the compressed air sup-

ply, make sure that the main air valve is

closed.

Caution!

The specified minimum primary air

pressure for operating the oil + air lu-

brication system must be maintained.

The compressed air must be dry and filtered. A

water separator, preferably with semi-automatic

drainage, is recommended for the preparation of

compressed air.

Detailed requirements for the compressed air are

listed in Table 3. The following applies regarding

the air volume required:

Higher-viscosity lubricant requires a larger volume

of air to transport the oil streak in the lubrication

point line.

Larger air volumes must be provided due to the

greater adhesion of high-viscosity lubricants to the

wall of the lubrication point line.

The compressed air to be used must comply with

at least quality class 3 as defined by DIN ISO

8573-1:

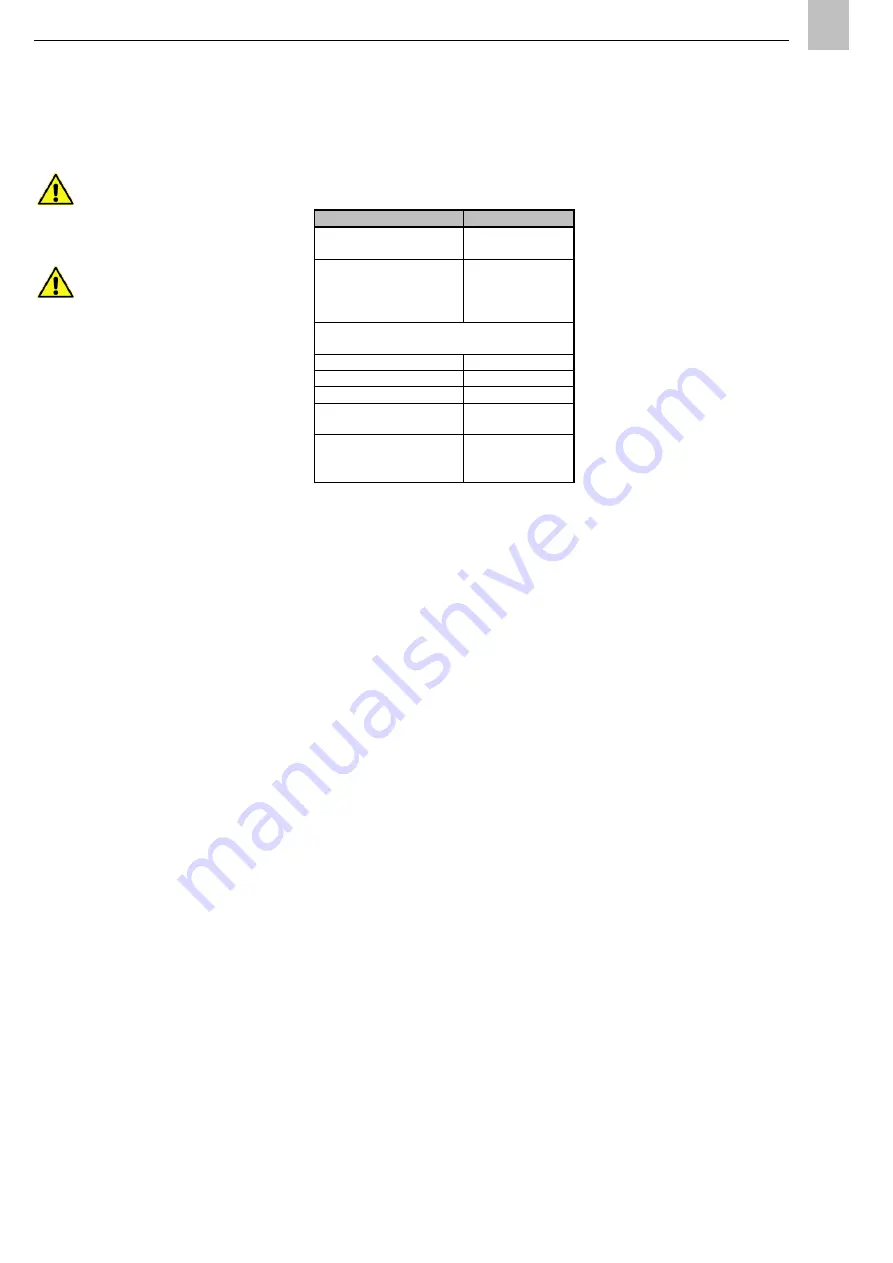

Table 3: Requirements for compressed air

Compressed air preparation can be optimized and

machine downtime and high maintenance costs

avoided by using compressed air of the appropriate

quality class.

The connection for the compressed air line is

designed as an M10x1 pipe thread with a counter-

bore for a solderless pipe union per

DIN 3854/DIN 3862 for pipe Ø 6 mm. The follow-

ing fittings are required to install the compressed

air line:

Compressed air line, metal tubing Ø 6 mm:

406-001 Double tapered sleeve

406-002 Socket union

Compressed air line, plastic tubing Ø 6 mm:

406-603 Reinforcing socket

406-611 Tapered sleeve

406-612 Socket union

A switch valve, e.g., a 3/2 directional control valve

(Fig. 4, item 24), is recommended in the air inlet

line for compressed air so that the compressed air

supply can be switched on and off.

Requirement

Values

Inlet pressure

min. 3 bar

max. 10 bar

Air volume required

(line with 2.3 mm internal

diameter, recommended oil

viscosity range)

1000 - 1500 l/h

Based on quality classes of compressed air per

DIN ISO 8573-1

Particle content

Class 3

Maximum particle size

5 µm

Maximum particle content

5 mg/m³

Pressure dew point

Class 4

maximum: +3 °C

Oil concentration

Class 3

maximum:

1 mg/m³

Summary of Contents for OLA Series

Page 19: ...3 Design and function page 19 EN Figure 4 Hydraulic diagram of oil air lubrication system ...

Page 49: ...blank page ...

Page 50: ...blank page ...

Page 51: ...blank page ...