Section 04

ENGINE

Subsection 03

(LEAK TEST AND ENGINE DIMENSION MEASUREMENT)

04-03-2

Engine

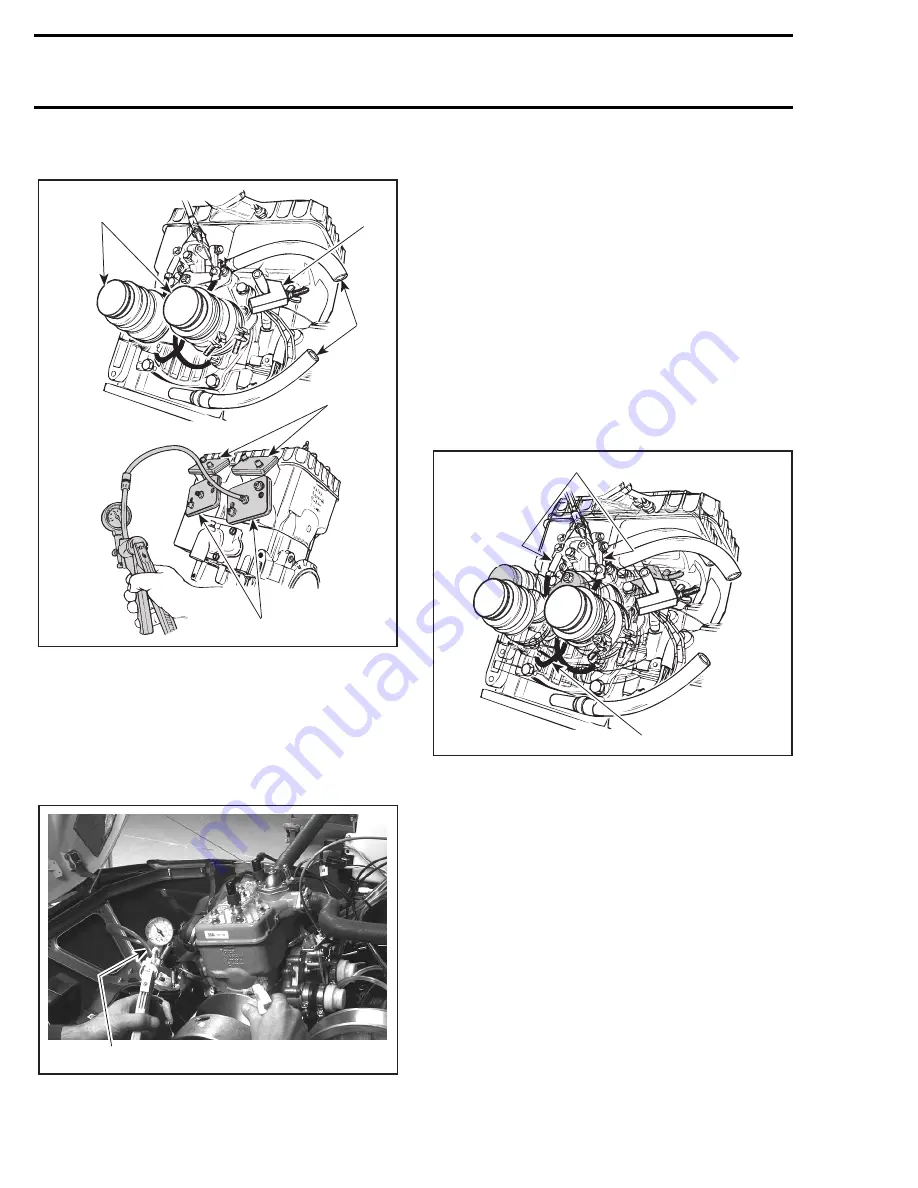

TYPICAL

1. Blocked intake flanges

2. Blocked impulse fitting

3. Open ends (if applicable)

4. Blocked RAVE valve flanges (if applicable)

5. Blocked exhaust flanges

When exhaust manifold is installed, use rubber

plug. (In this case it is not necessary to move pis-

ton to BDC).

1. Rubber plug

Check the following:

1. All jointed surfaces and screw/stud threads of

engine:

– spark plug base, insulator

– cylinder head

– cylinder base

– crankcase halves (joint)

– rotary valve cover

– oil injection pump mounting flange

(O-ring, seal)

– coolant pump housing

– bleed screws/plugs

2. Small injection oil lines coming from pump.

1. Banjo fittings

2. Small injection oil lines

Check for air bubbles or oil column going toward

pump. It indicates defective check valve in banjo

fitting (or lines).

3. Remove cooling system cap.

Check for air bubbles in antifreeze. It indicates de-

fective cylinder head O-ring or cylinder base gas-

ket.

A01B4TA

1

2

3

4

5

A01B4BA

1

A01B2XA

1

2

Summary of Contents for Formula MACH 1

Page 1: ......

Page 277: ...FORMULA 111 600 600 R 600 LT 700 700 R MACH 1 1 R ANNEX 1...

Page 278: ......

Page 279: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 283: ...MACH Z Z R Z LT Z LT R ANNEX 2...

Page 284: ......

Page 285: ......

Page 286: ......

Page 287: ......

Page 288: ......

Page 289: ...GT 700 ANNEX 3...

Page 290: ......

Page 291: ......

Page 292: ......

Page 293: ......

Page 294: ......

Page 295: ......

Page 296: ...GT SE ANNEX 4...

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......