8

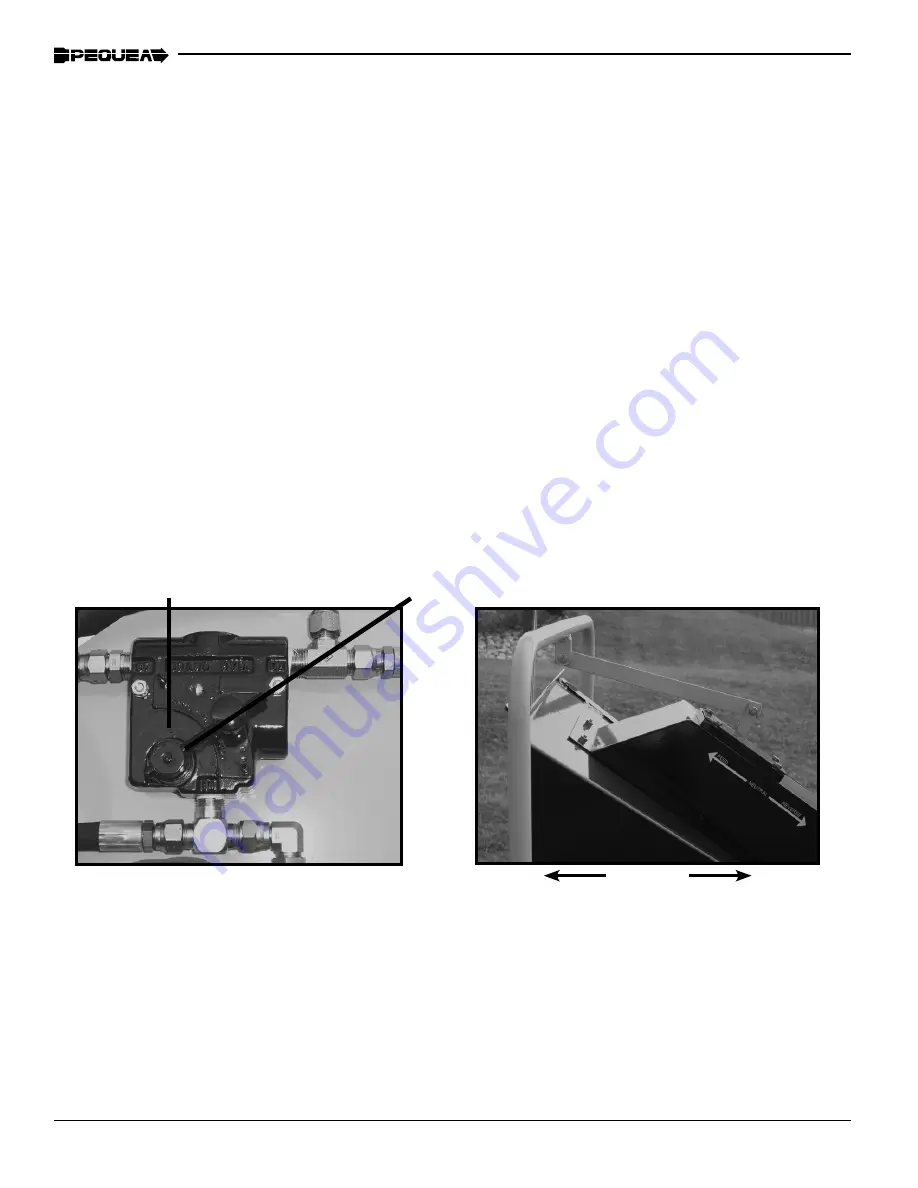

The flow control valve (Figure 5) will control the speed of the material being fed into the chipper.

The tractor’s hydraulic pressure and will also contribute to the speed of the feed.

To adjust the speed of the feed system, find a small branch and feed it into the chipper at with the

feed adjusted to 3 or 4 and keep adjusting up until the chips are 3/8 to 1/2 inch thick. The feed set-

ting “0” will completely stop the flow of oil to the motor, stopping the feed roller

The hydraulic system on the chipper requires at least 6 GPM to operate the chipper at full capac-

ity. If the tractor has too much flow the oil in the tractor could overheat, causing the hydraulic fluid

to lose it’s viscosity. In this situation a self contained hydraulic kit should be installed. This option is

available from Pequea. Contact your local dealer/distributor for pricing and availability.

Sometimes when the brush is wet or if there are a lot of small twigs and branches the feed roller

can slip because of the wet wood or of the small sized material. In this situation it is best to grab the

control bar and switch from forward to reverse several times. You can even reverse the material and

rotate it a different way so that the roller grabs a different part of the branch.

OPERATION

Feeding Material

Shown above (Figure 6) is the control bar that operates the feed roller. This control bar has

three positions, forward, neutral, & reverse. The feeding position is to the rear of the machine so

that in an emergency the operator can just push the control bar and it will either stop or reverse

the feed roller. Always keep the control bar in the neutral position whenever you are not feeding

the chipper to eliminate the chance of accidently feeding something into the machine.

0

10

Figure 5

Hydraulic Flow Control

Forward

Neutral

Reverse

Figure 6

Summary of Contents for PEQUEA CX551

Page 16: ...14 NOTES...

Page 17: ...15...