6. Always allow cutter to come up to operating speed before moving attachment

into the material you want to cut.

7. If material constantly is balling underneath cutter deck, try tilting the leading edge

of the cutter to be about 1" lower than the rear of the cutter. This should allow a more

efficient material flow under the cutter deck.

8. Use the v-notch in the top of the cutter deck to capture small trees (up to 3"

(76mm) for cutting.

Vertical Cutting

Your Articulating Brush Cutter has the capability to cut vertically to widen pathways,

roadways, or along the edge of a crop field to allow access for tractors and combines.

Vertical cutting can disperse debris over a large area. To avoid an accident that could

result in Death or Serious Injury, do not operate the cutter when bystanders are within

300' (91m).

To avoid Minor or Serious Injury, never swing the cutter boom past the side tipping

capacity of your skid steer when the cutter is in the raised and vertical position. Know the

capability of your machine and notice the terrain you are working on. Raise the skid steer

loader arm and tilt the cutter head to the vertical position. Swing the boom to the right

to access the area to be cut. Raise and lower the skid steer's lift to trim back over-

hanging branches.

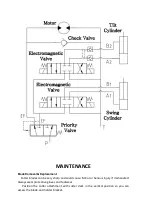

HYDRAULIC ELECTRIC CONTROL SYSTEM

Read all safety decals and safety statements in all manuals before beginning any

hydraulic connection. Know and obey all OSHA regulations, local laws, and other

professional guidelines for your operation. Know and follow good work practices when

assembling, maintaining, repairing, mounting, removing, or operating this equipment.

Loaders

1. Disconnect the hydraulic hose quick couplers from one another and attach the quick

couplers to your prime mover as per the instructions in your prime mover's operator's

manual.

2. Carefully raise the loader and cycle the rollback/dump cylinders to check hose

clearances and to check for any interference. Operate the hydraulic cylinder(s) on this

product to make the same checks.

3. Cycle the hydraulic cylinder(s) on this product several times from fully retracted to

fully extended until all air has been completely removed from the cylinder(s).