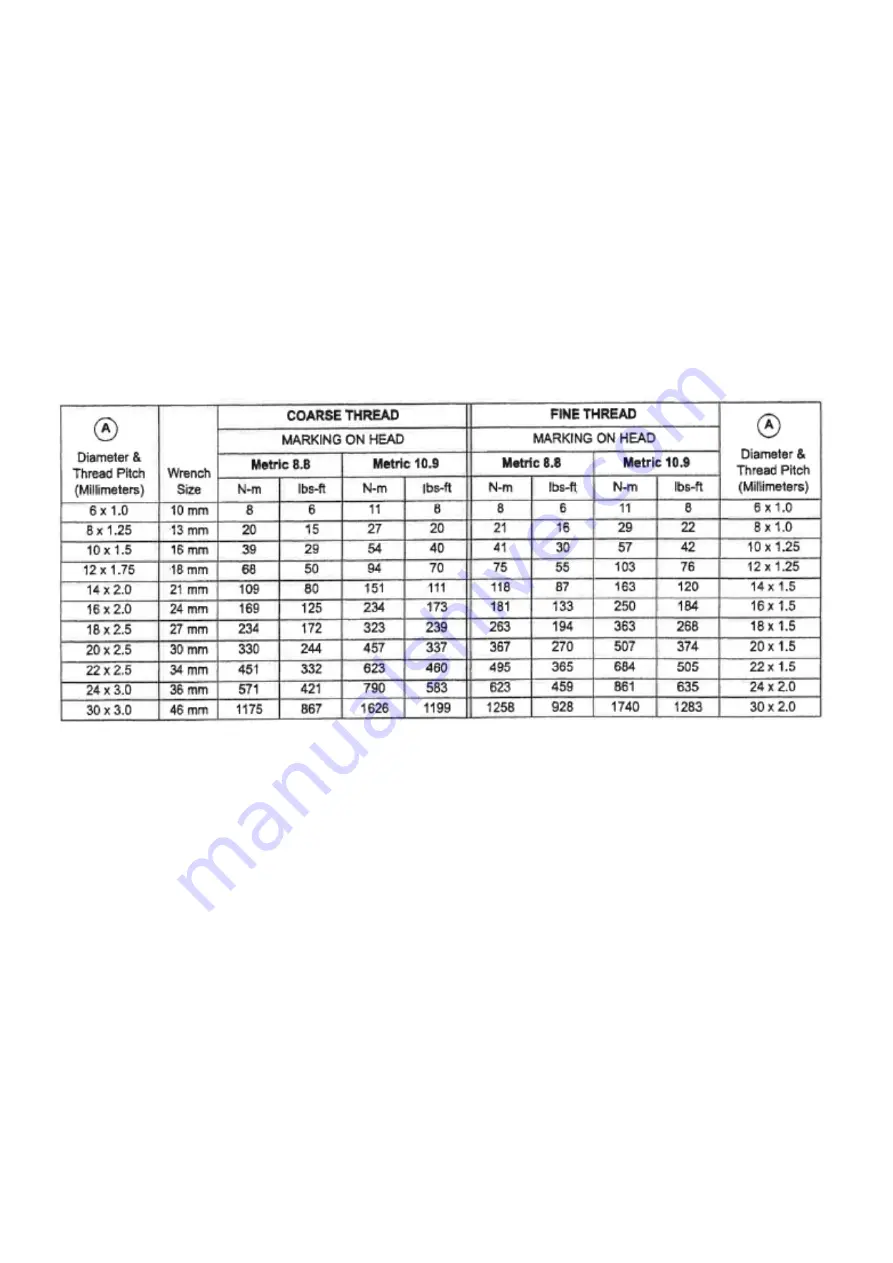

BOLT TORQUE SPECIFICATIONS

GENERAL TORQUE SPECIFICATION TABLES

Use the following charts when determining bolt torque specifications when special

torques are not given. Always use grade 8.8 or better when replacing bolts.

METRIC BOLT TORQUE SPECIFICATIONS

The following torque values are for use with metric Bolt head identification marks as per

grade. hardware that is unplated and either dry or lubricated with engine oil. Reduce

torque 15% when using hardware that has extreme pressure lubricants, plating or hard

washer applications.