GENERAL SAFETY PRECAUTIONS

Operator Safety

It is the responsibility of the operator using this attachment to be acquainted with the

safe operation. In addition to reading this manual, it is important that the operator read

the skid steer's operation manual and follow its manufacturer's recommendations!

& Before raising, lowering or swinging the cutter, make sure area is clear of bystanders or

objects.

Machinery parts sometimes have sharp edges. Wear work gloves when moving parts.

Always use caution around cutter blades as they often are very sharp.

Never use drugs or alcoholic drinks when operating or servicing this piece of equipment.

Always wear the proper personal protection equipment when servicing or operating

this piece of equipment. Never service or operate this attachment with bare feet, sandals,

or another light footwear.

Always use eye protection during operation. Mount this attachment on a skid steer

equipped with thermoplastic polycarbonate door panel and side panels.

Speed Kills! Operate this implement at a safe working speed. When transporting the

implement, keep a safe speed to avoid losing control of the attachment or prime mover.

Keep proper clearance between the implement and objects (tree stumps, large rocks,

buildings, etc.). Contacting these objects with the implement or prime mover could cause

a loss of control or damage to the implement.

Before each operation of this implement, check all hardware (bolts, nuts, pins, cotter

pins, etc.) for their proper location and tightness.

Stop the engine on the skid steer and set the brake to avoid the implement rolling

forward or backwards while you are exiting the prime mover.

Store this implement in an area not frequented by children.

Allow no riders on this attachment. Keep all bystanders clear of attachment during

operation.

Always replace worn, torn or missing safety decals before operating.

Never operate the cutter when bystanders are within 300 feet of the work area.

Use caution when performing service work on or near the machine's battery. Do not

smoke near the battery as battery vapors could ignite.

Skid Steer Requirements

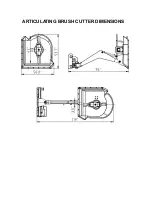

The Articulating Brush Cutter should only be used on skid steers with a lift capacity of

at least 1800 Ibs. and with a weight of at least 6500 with the bucket removed. A skid

steer equipped with tracks will provide superior stability in this application.

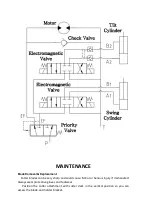

You will install the electrical joystick that accompanies this attachment or your skid

steer must be equipped with an auxiliary electrical option with an electrical connector

mounted on the machine's loader lift arm from the skid steer manufacturer. In order to

complete the connection, the mating connector on the loader arm needs to match the

connector from the attachment.

A 12 V power source coming directly from the battery or from some other circuit that

is energized all the time could result in Death or Serious Injury if the attachment control