BASIC PARAMETER

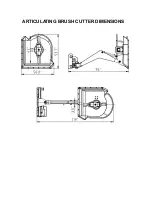

OF ARTICULATING BRUSH CUTTER

Num

Item

Parameter

Remark

1

Overall Length

94"(vertical)

119"(tilt)

model:ZABC42

2

Overall wide

50.8"

3

Overall height

53.7"

4

Cutting Width

42"

5

Material Cutting

Up to 5 in dia

6

Cutting Blades

9/16x11.5x5

2 Blades

7

Max Swing Degree

90°

8

Max Head Tilt Degree

35°

9

Hydraulic Flow Required

14-20GPM

10

Max. pressure of oil

2000-2500 psi

11

Direct Current Voltage

DC12V

12

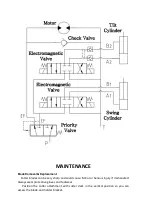

Check Valve

CIT-03 G3/8

13

hydraulic cylinder

2.5"x1.5"x16〞

Stroke 16〞

14

hydraulic cylinder

2"x1.25"x8〞

Stroke 8〞

15

hydraulic control valve

Flow

25GPM

16

hydraulic control valve

pressure

3500 psi

17

Gearbox

XH30.192Z.01L/03L

Speed Increasing Ratio

1:1.92

18

Chain Roller

No.50

Chain Link 16

19

Weight

948 lbs

20 GPM MAX