INSTALLATION & SET-UP

Using Your Implement Connecting Cutter to Skid Steer

Verify that the hydraulic hoses and the wire harness are clear from the front of the

attaching plate on the attachment and that the mounting plate is free from dirt and

debris. When clear, move the skid steer to proximity of attachment plate. Tilt skid steer

coupler forward to align coupling point with the upper part on the attachment plate and

raise the coupler slightly.

Connecting Coupler to Attachment

When the top edge of the coupler is seated in the top part of the coupler plate, roll

the skid steer tilt function back until the attaching plate is flat against the skid steer

coupler. Lock down the coupler levers.

Wipe off any dirt or dust from the male or female hydraulic flat-face couplers with a

clean rag before attaching hoses, to keep contaminants from entering the hydraulic

system.

Connect the cutter hydraulic hoses to the auxiliary circuit connectors on the skid

steer. Connect the electrical harness to the appropriate connector on the skid steer.

Check the surrounding area for bystanders and clear them before starting the skid

steer or attachment.

Before operating the attachment, always visually inspect and verify that the coupler

lock pins are fully engaged through the latch slots on the attachment plate.

Never enter the area underneath the coupler or any part of the attachment when it

is in the raised position to avoid an accident that will result in Death or Serious Injury.

OPERATING INSTRUCTIONS

Cutter Boom Controls

The joystick control can be easily attached to the leg of the operator using the Velcro

straps provided.

Always turn the engine "off and remove the joystick controller from your leg before

exiting the skid steer cab to avoid unwanted machine or attachment movement that

could cause Death or Serious Injury.

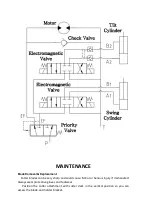

In order to swing or tilt the cutter head, the auxiliary hydraulics to the cutter drive

must be turned on.

During operation you may notice that the cutter speed slows down a little while you

are activating the swing or cutter deck tilt. When you have completed swinging the boom

or tilting the cutter deck, the cutter will resume to its normal rotation speed.