●

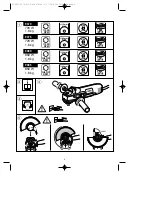

Mounting of accessories

6

! disconnect the plug

- clean spindle C and all parts to be mounted

- tighten clamping flange E with spanner F while

pushing spindle-lock button G

- for removing accessories handle vice-versa

! grinding/cutting discs become very hot during

use; do not touch them until they have cooled

down

! always mount backing pad when using sanding

accessories

! never use a grinding/cutting disc without the label

(“blotter”) which is glued onto it

●

Before using the tool

- ensure that accessory is correctly mounted and firmly

tightened

- check if accessory runs freely by turning it by hand

- test-run tool for at least 30 seconds at highest no-load

speed in a safe position

- stop immediately in case of considerable vibration or

other defects and check tool to determine the cause

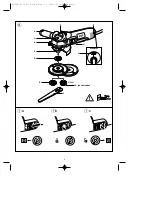

●

On/off locking switch H

7

- switch on tool

7

a

! be aware of the sudden impact when the tool is

switched on

! before the accessory reaches the workpiece, the

tool should run at full speed

- lock switch

7

b

- unlock switch/switch off tool

7

c

! before switching off the tool, you should lift it

from the workpiece

! the accessory continues to rotate for a short time

after the tool has been switched off

●

Speed selection wheel L

6

(9380/9385)

-

for determining the right speed table

0

can be used

as reference

! always test out first on a piece of scrap material

●

Electronic soft-start

(9380/9385)

Ensures reaching the maximum speed smoothly without

a sudden impact when tool is switched on

●

Electronic constant speed

(9380/9385)

Keeps the speed at a constant level as the load

increases

●

Electronic overload protection

(9380/9385)

Stops the motor automatically in case the tool is

overloaded for a longer period of time

For restarting the motor:

-

switch off tool

-

let tool cool down for 30 seconds

-

switch on tool

●

Grinding

8

- move the tool back and forth with moderate pressure

! never use a cutting disc for side grinding

●

Cutting

9

- do not tilt the tool while cutting

- always move the tool in same direction as arrow on

tool head, in order to prevent the tool from being

pushed out of the cut in an uncontrolled manner

- do not apply pressure on the tool; let the speed of the

cutting disc do the work

- the working speed of the cutting disc depends on the

material to be cut

- do not brake cutting discs with side pressure

●

Holding and guiding the tool

- always hold the tool firmly with both hands, so you

will have full control of the tool at all times

- provide for a secure stance

- pay attention to the direction of rotation; always hold

the tool so, that sparks and grinding/cutting dust fly

away from the body

- keep ventilation slots J

6

clear and uncovered

APPLICATION ADVICE

●

Instead of flange E

6

the ”CLIC” quick-clamping flange

K

6

(SKIL accessory 2610388766) can be used;

grinding/cutting discs can then be mounted without the

use of accessory keys

GUARANTEE / ENVIRONMENT

●

Always keep tool and cord clean (especially the

ventilation slots)

! do not attempt to clean ventilation slots by

inserting pointed objects through openings

! disconnect the plug before cleaning

●

This SKIL product is guaranteed in accordance with

statutory/country-specific regulations; damage due to

normal wear and tear, overload or improper handling will

be excluded from the guarantee

●

In case of a complaint, send the tool

undismantled

together with proof of purchase to your dealer or the

nearest SKIL service station (addresses as well as the

service diagram of the tool are listed on

www.skileurope.com)

●

Dispose of the tool by sorting tool, accessories and

packaging for environment-friendly recycling (the plastic

components are labeled for categorized recycling)

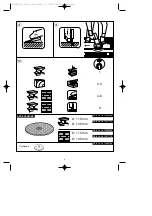

INTRODUCTION

●

Cet outil sert au meulage, au tronçonnage et à

l'ébarbage de pièces en métal et en pierre sans utiliser

de l'eau; combiné avec des accessoires spécifiques, cet

outil peut également servir au brossage et au ponçage

SPECIFICATIONS TECHNIQUES

1

F

6

XP SKIL 9370/9375/9380/9385.2 17-06-2003 10:36 Pagina 6