Page 7 of 18

Date: 2019-02-12

8

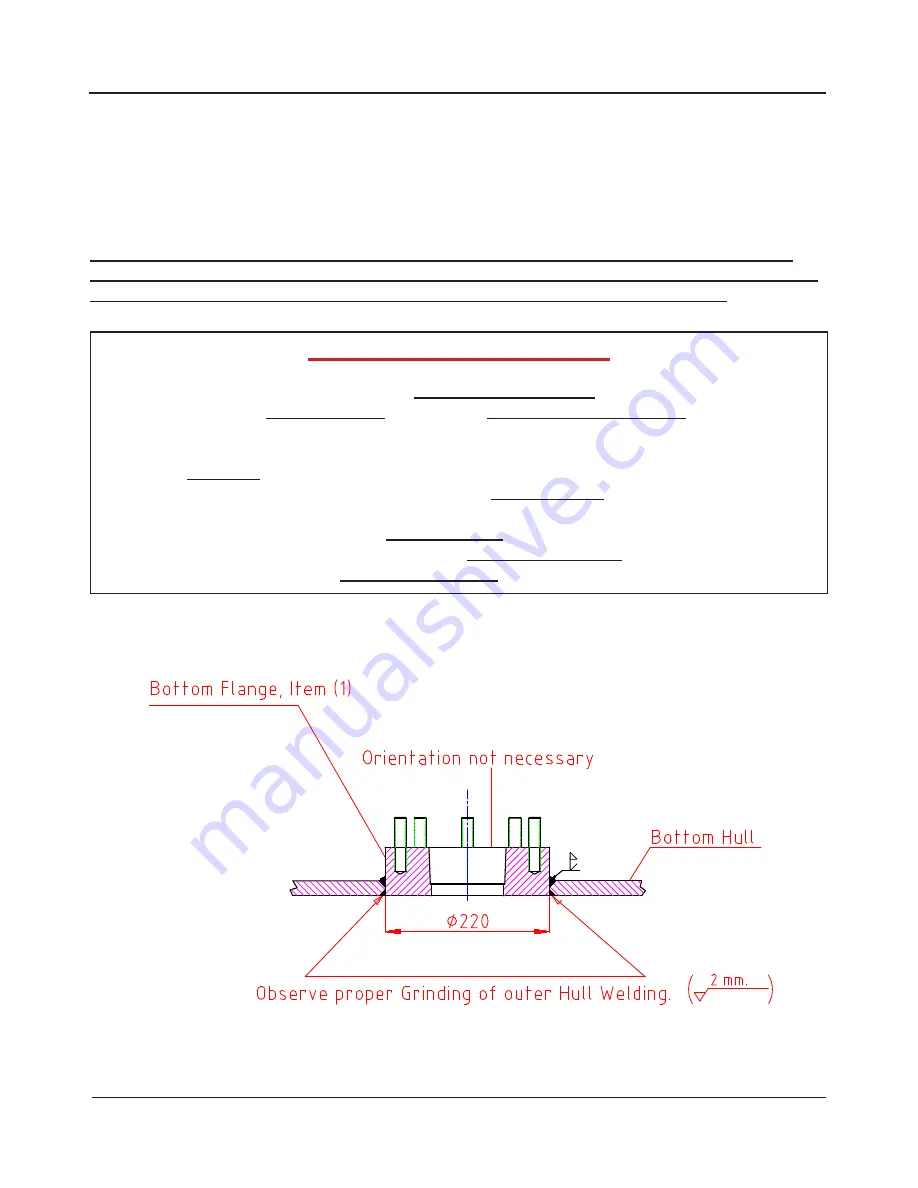

3. Welding the bottom flange

• When the position has been decided, a 220 mm hole is cut in the hull.

•

The bottom flange, Item (1), is welded into the hull. Standard welding practice, methods and procedures

should be observed, but may vary. (See welding notes).

Attention:

The bottom flange is a part of the Sea Valve that is machined with high accuracy and it should be

protected after mounting to avoid damage to the bottom flange surfaces. This to avoid leakage. If the

valve is pre-mounted, be sure to protect the valve from being polluted by welding debris.

WELDING NOTES!

All bottom parts and flanges for welding are

precisely machined parts. During welding of these parts

to the ship’s hull plates, careful attention must be paid to avoid construction strain on the bottom

parts and flanges.

• Let parts cool down during welding.

•

Over heating may change fit and form and result in

non-conformity with intended sensor/

transducer.

• Welding to thick hull steel plates will

exert high stress on bottom parts and flanges.

• Especially care must be taken during welding of

stainless steel flanges.

• Work must be performed by a

qualified and certified

welder.

Welding the bottom flange in ship’s hull.

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual