9

SKOPE B1200-2/B1200G-2

Operation

User Manual

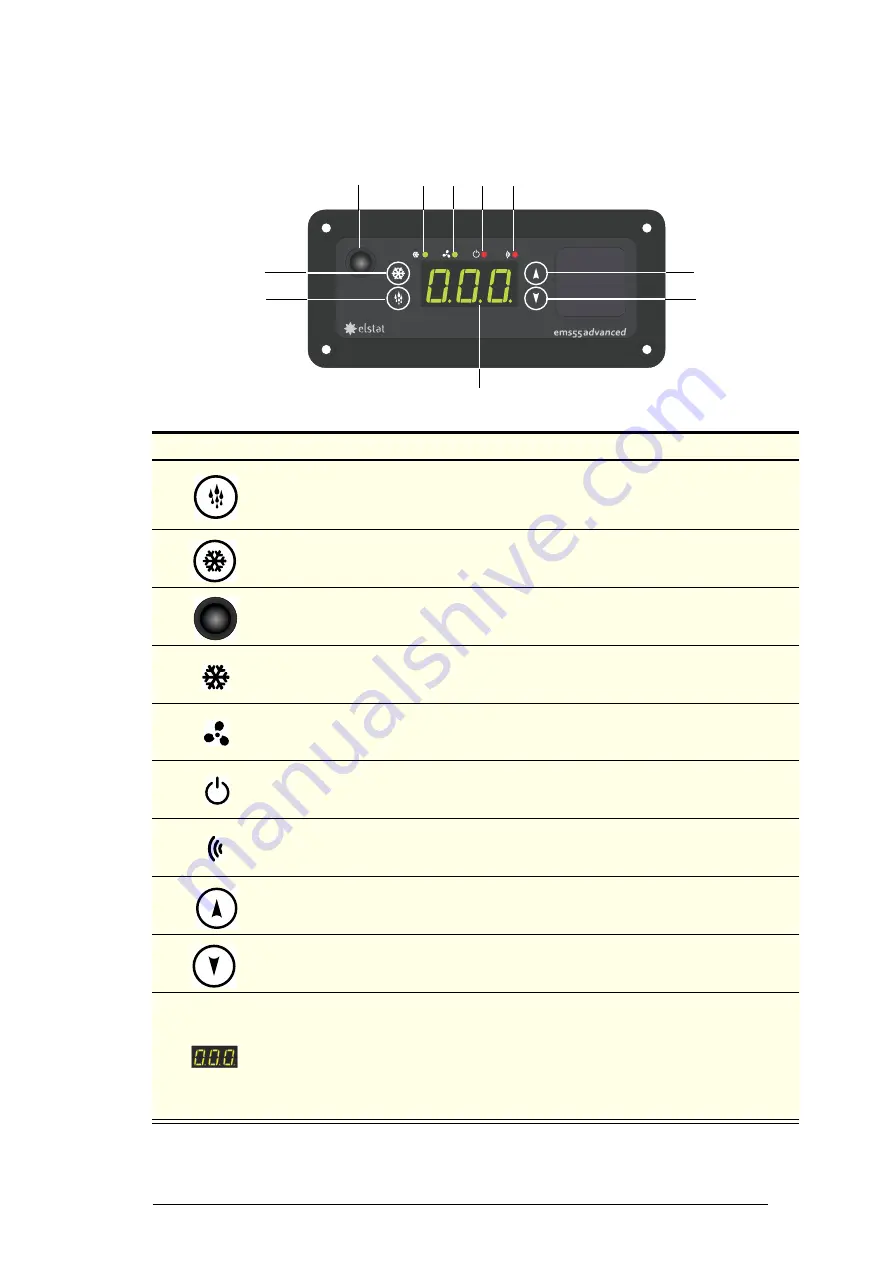

Faceplate

Because the EMS Advanced controller plays such an important role, it’s

helpful to know the parts of the faceplate you will use.

No.

Item

Description

1

DEFROST

button. Manually activates an additional defrost cycle, and used to program

the controller.

The first automatic defrost occurs six hours after the first off-cycle.

2

SET

button.

Used to program the controller.

3

Eye of the infrared motion sensor. It detects activity within five metres around the front

of the chiller, and feeds the data to the EMS advanced controller.

4

LED for the compressor light – green when on.

5

LED for the evaporator fan – green when on.

6

LED indicating perishable mode – red when on. See page 10 for more information.

7

LED linked to the motion sensor and flashes red when there is activity around the

chiller, but otherwise off.

8

UP

button. Used to program the controller.

9

DOWN

button. Used to program the controller.

10

Digital display of cabinet temperature or messages (see next page for details).

The temperature is what the sensor inside the chiller detects, and not necessarily the

product temperature. However, they may be very close depending on how the

controller is set to sense temperature.

When the chiller is in stand-by mode, the controller displays three bars (- - -). This

should not be displayed during normal business hours.

8

9

1

2

3

4

5

6

7

10