4

Technical User Guide

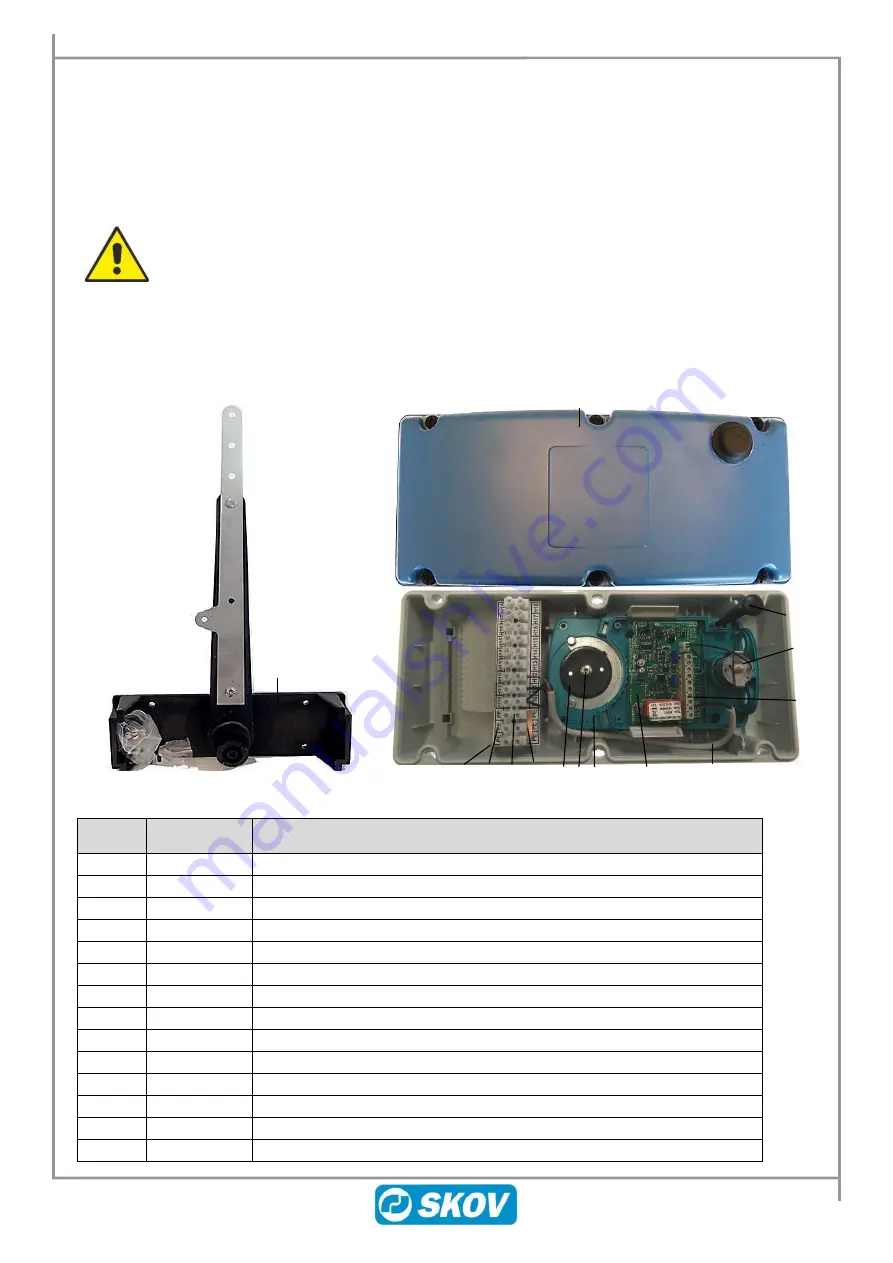

DA 74BC Winch Motor

1

Product Description

DA 74BC is a 24V winch motor with a wall fitting and an arm which is used to adjust wall inlets, ceiling inlets

or emergency opening of windows and doors in houses.

DA 74BC can be mounted for either ON/OFF or stepless regulation and is controlled by a house computer. The

winch motor can be operated manually by disconnecting power, activating the push button for the manual

release and turning the wall fitting arm.

Before activating the manual release, you

must

retain the wall fitting arm.

DA 74BC can be set to ON/OFF, stepless, ON/OFF reverse or stepless reverse using the jumper on the PCB.

DA 74BC is controlled by 24V DC, ensuring safe emergency opening in case of a power failure or other

failure.

DA 74BC is easy to clean thanks to its compact design.

Figure 1: DA 74BC

Position

Article no.

Winch motor DA 74BC

1

527272

DA 74 cover incl. quarterturn screws

2

301074

Relay cable 0.75 mm 2x300 + 1x80

3

Retaining disc

4

Locking screw

5

432950

Gear unit complete (green)

6

290074

PCB

7

Connection terminals on PCB

8

432952

Motor

9

Push rod manual release

10

310323

Mounting clip for DIN rail, black

11

344174

Label for DA 74 terminal block 12p

12

310000

Terminal block 12P 4 mm2

13

310237

Phase busbar cobber 3p 10mm-spacing

14

432090

DA 74 wall fitting for wire pull

1

14

2

4 5

6

9

8

7

10 11

13 3

12