48

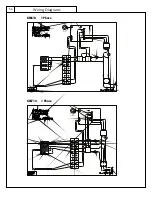

Appendix 6 — Set-up and specifications for PK kilns

PK production kilns

Skutt PK production kilns are heavy duty, high capacity units designed

to meet the needs of the high fire production potter, tile maker

and light industrial user. These kilns are equipped with upgraded

components and wiring that will allow them to high fire extremely

dense loads in a relatively short time.

Firing

Skutt PK kilns feature our KilnMaster controller, so operation is identical

to other KM kilns. Even though the earlier sections of this manual

do not refer specifically to the PK kiln line, you may follow all the

instructions on programming and firing routines.

Kiln Improvements

If you are an intensive kiln user, you might find a PK kiln to be the appropriate choice for your next

kiln purchase. Here are some of the differences from our standard KM kiln line

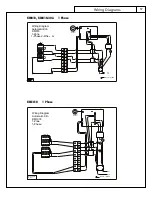

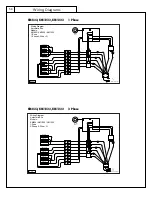

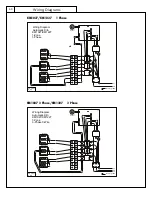

First, PK kilns are designed to fire full, Cone 10 loads without stalling on the high end. To do so, they

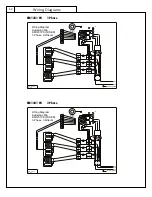

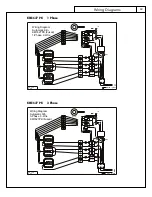

are equipped with industrial gauge wiring and three types of elements for better firing balance.

Because of their high rating, electrical codes require that they be direct wired by an electrician;

therefore no plug is included.

Mercury displacement relays are used for longer life and quieter operation.

The hinged control box is larger, and compression connectors are used on the feeder wires for

easier element replacement.

Finally, Model KM1231PK comes with an additional stand for bottom slab support under heavy

loads.

Unpacking and Moving PK Kilns

Follow the general instructions on kiln set-up found in this manual. You will probably want to

separate the kiln into sections when you set it up or move it to a different location. These instructions

are slightly different than for standard KM kilns.

C

aution

:

Before disassembling any PK kiln, be sure to turn off power to the kiln by throwing the

circuit breaker or removing the fuse on its circuit. Do not restore power to the kiln until it is fully

reassembled.

n

ote

:

The mercury relays in the switch box must be operated only with the switch box in a normal,

vertical orientation.

Appendices