Summary of Contents for Maxi Drill 6000

Page 2: ......

Page 28: ...26 Mise en route Start up Inbetriebsetzung D 1 2 3 3 ...

Page 30: ...28 Mise en route Start up Inbetriebsetzung D 1 2 ...

Page 32: ...30 Mise en route Start up Inbetriebsetzung E ...

Page 42: ...40 Mise en route Start up Inbetriebsetzung L 2 3 4 1 ...

Page 50: ...48 Réglages Settings Einstellungen C 3 4 2 1 ...

Page 54: ...52 Réglages Settings Einstellungen D ...

Page 64: ...62 A Fertisem 1 2 a a b c ...

Page 68: ...66 Fertisem B 2 1 3 ...

Page 70: ...68 Fertisem D 1 2 ...

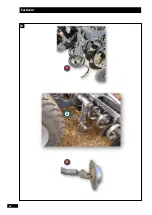

Page 74: ...72 Entretien Maintenance Wartung B ...

Page 94: ...92 Entretien Maintenance Wartung J Maxi Drill ...

Page 98: ...96 Conseils Techniques Technical advice Technische Hinweise B ...