Sky Climber

ZEABORN GUIDELINES

- Page 33 -

18.11.2020 Version 1

5.4.2.2 Inspecting load support performance

1) Raise the pl/- 10cm of the surface with the Sky Climber hoist.

2) Engage (trip) the Sky Lock brake onto the wire rope by activating the manual trip lever on the brake.

3) Operate the Sky Climber hoist in the

“DOWN” direction. The system should not descend, because

the Sky Lock brake will be locked onto the wire rope and supporting the system.

4)

Operate the hoist in the “UP” direction approximately 5 cm to relieve the load from the Sky Lock

brake.

5) Manually reset the Sky Lock fall arrest device.

WARNING: Do not attempt to adjust or repair the Sky lock brake. It is a precision device

and must be handled carefully.

5.5 OVER- UNDERLOAD CALIBRATION AND INSPECTION

In order to protect the over-/underload device from unauthorised adjustment, calibration of this device

requires a special tool. Refer to the “Safety Devices Assembly Manual” for more details on this tool.

5.5.1 Calibration of the overload device

1) Raise the pl/- 10cm of the surface with the Sky Climber hoist.

2) Load the platform with the maximum load specified in table 2.

3) Turn the lower ring on the OL bushing assembly upwards until the OL switch activates the audio

alarm.

4) Remove some of the load until the working load level is reached. The overload switch shall not be

activated at this load.

5) Whenever the load on the platform exceeds the trigger level, an audio alarm will occur and the

overload device will prevent the hoist from moving upwards.

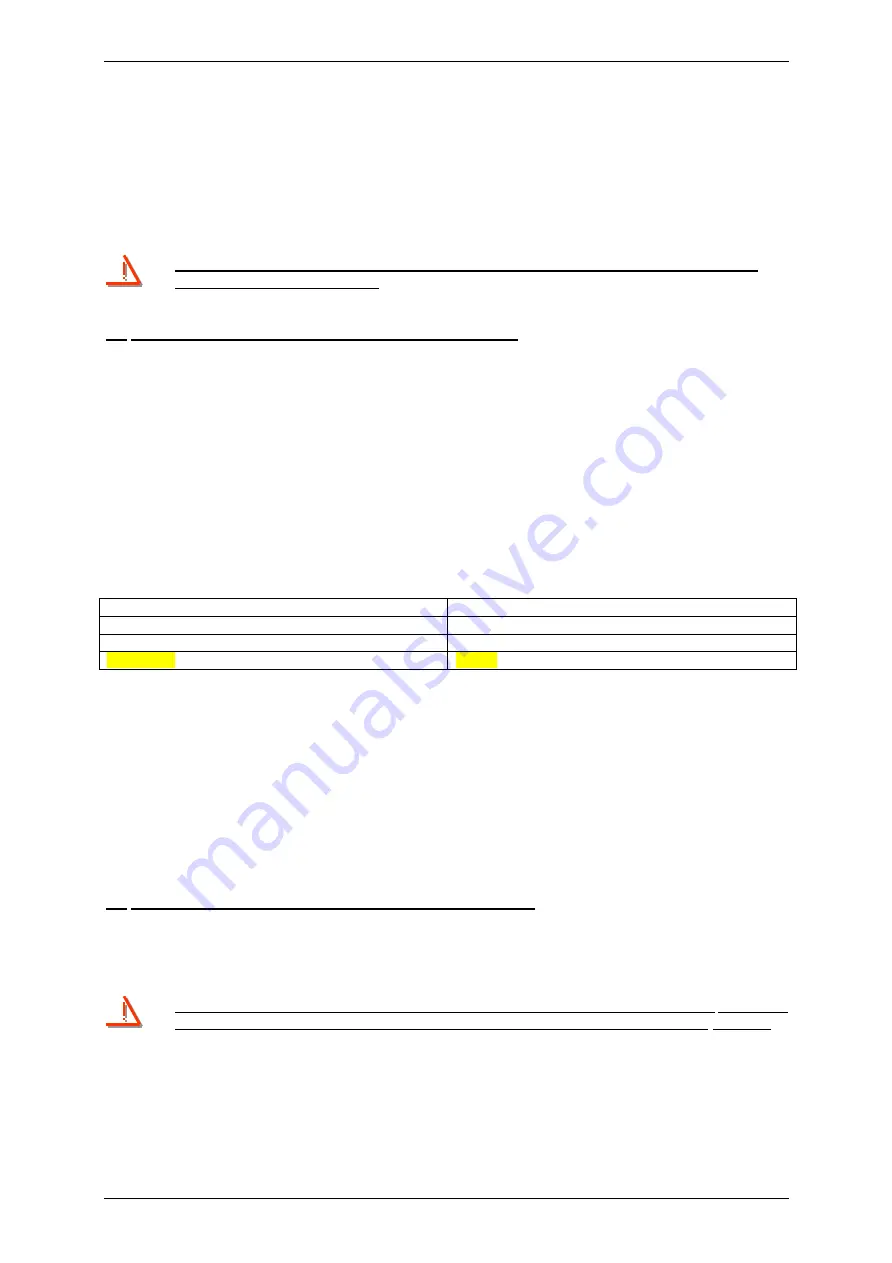

Compact

480kg

CX500

600kg

Alpha 500

600kg

Alpha 800

960kg

Table 2

– Trigger levels overload device

5.5.2 Calibration of the underload device

1) Raise the pl/- 10cm of the surface with the Sky Climber hoist.

2) Load the platform with the intended working load.

3) Turn the upper ring on the UL bushing assembly downwards until the UL switch activates the audio

alarm.

4) Turn the upper ring slightly back until the alarm stops.

5) Whenever the load on the platform decreases the intended working load, an audio alarm will occur

and the underload device shall prevent the hoist from moving downwards.

5.6 HOIST COMPONENTS INSPECTION AND MAINTENANCE

Maintenance of the Sky Climber equipment requires special tools and training available only at Factory

authorized service centers. All Sky Climber Compact material must be returned to a Factory authorized

service center for inspection and maintenance after every 12 months of operation.

WARNING: Failure to have your equipment inspected and maintained by a Factory authorized

service center every 12 months, may result in serious personal injury or property damage.

Sky Climber hoists are lubricated for life. Under normal conditions, they will not require further

lubrication. However, if an oil leak is observed, return the hoist to a Factory authorized service center.