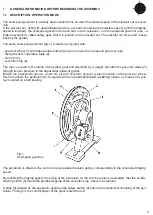

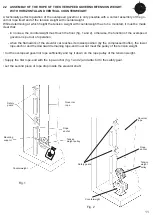

TENSION PULLEY WITH HORIZONTAL COUNTERWEIGHT

• Mount the mount ng support at about 450 mm (ap-

prox. value, fig. 3) on the bottom of the shaft.

• Hold the counterwe ght, unt l t s n an obl que pos -

t on (fig. 3).

• In the presence of a brake mechan sm act ng up-

wards, mount the second rope-end to the rope-an-

chor of the brake dev ce

or:

• Supply the second rope-end w th the rope-anchor

and attach t to the safety gear.

• Remove the support n order to stretch the rope.

If the assembly has been properly carr ed

out, the counterwe ght should take a sl ghty

upward angled pos t on (fig. 3).

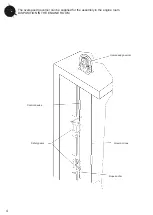

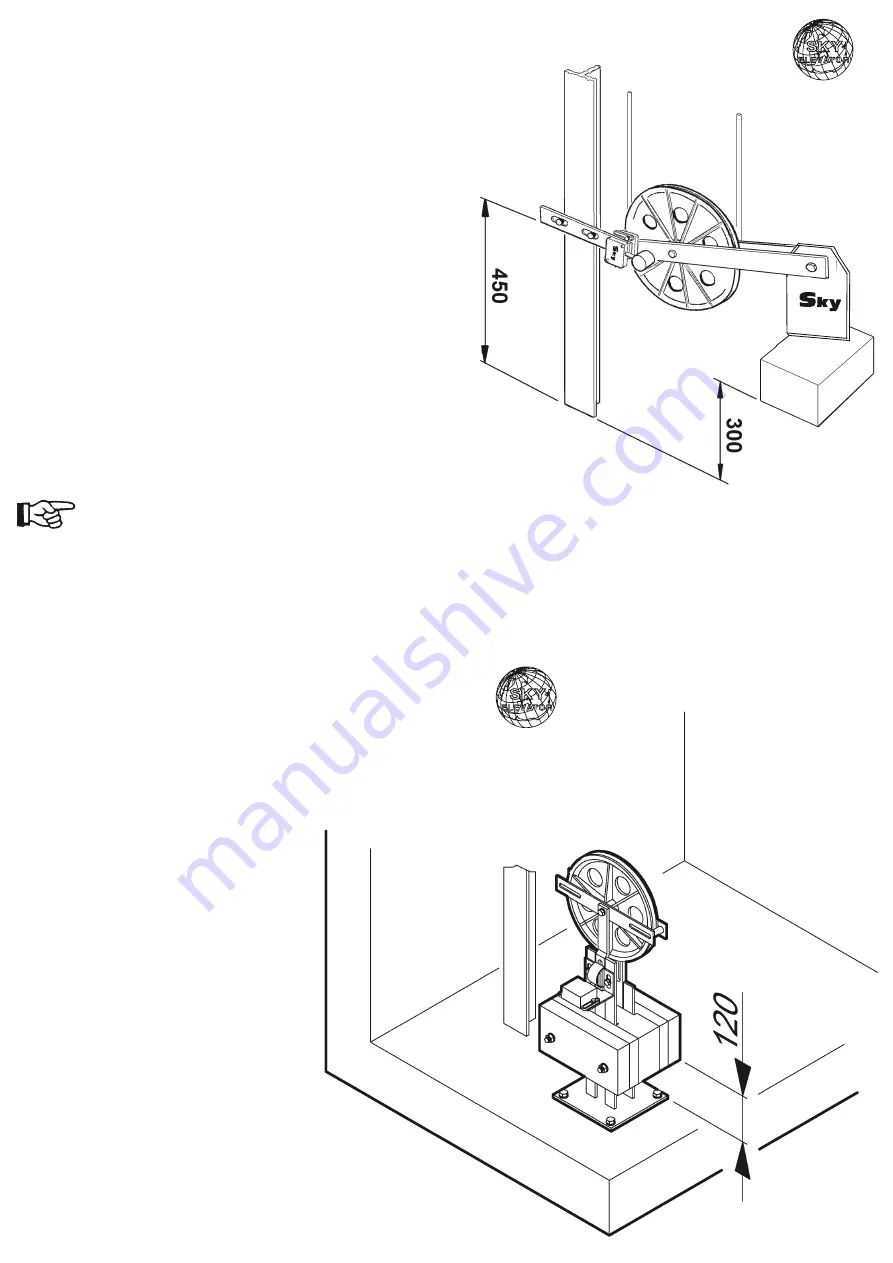

TENSION PULLEY WITH VERTICAL COUNTERWEIGHT

• Mount the lead ng plate of the

counterwe ght to ach eve per-

fect al gnment between the

pulley of the overspeed gover-

nor and the pulley of the ten-

s on we ght (fig. 4).

• Hold the counterwe ght, unt l t

reaches a he ght of about 120

mm from the bottom of the

shaft (approx.value) (fig. 4).

F g. 3

F g. 4

10KG

12