57

3.8 Scale Calibration

•

If you were to cut out any particular shape, for example,

a 10” x 10” square, you might find that it actually

measures 9-15/16

” x 10-1/32”. It will be very close to 10” x 10” but perhaps just slightly smaller or larger in

either or both dimensions. Now this might be perfectly acceptable for the type of cutting you do. Therefore, it

may not even be necessary to do this particular calibration. However, if you do want to make sure your

shapes are cut precisely to scale, the following procedure will allow you to calibrate your Skycut.

•

The calibration process can be conducted in inches, cm, or mm. Both mm and inches will be presented

here. In general, it is recommended that mm be used, however, if you do not have a metric ruler, then you

can use inches instead.

•

Before beginning this calibration, make sure the

Scale

setting on the Skycut itself is still set to 1.0 and 1.0.

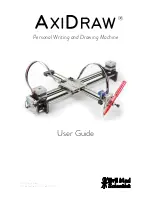

On the control panel, go to

MENU>Scale

. The following window opens where you can verify that the current

X

and

Y Scale

values are both set to 1.0000:

•

Return to the main screen. Then pick one of the two following sections and follow the instructions.

3.8.1 Scale Calibration Using Millimeters for Measurement

•

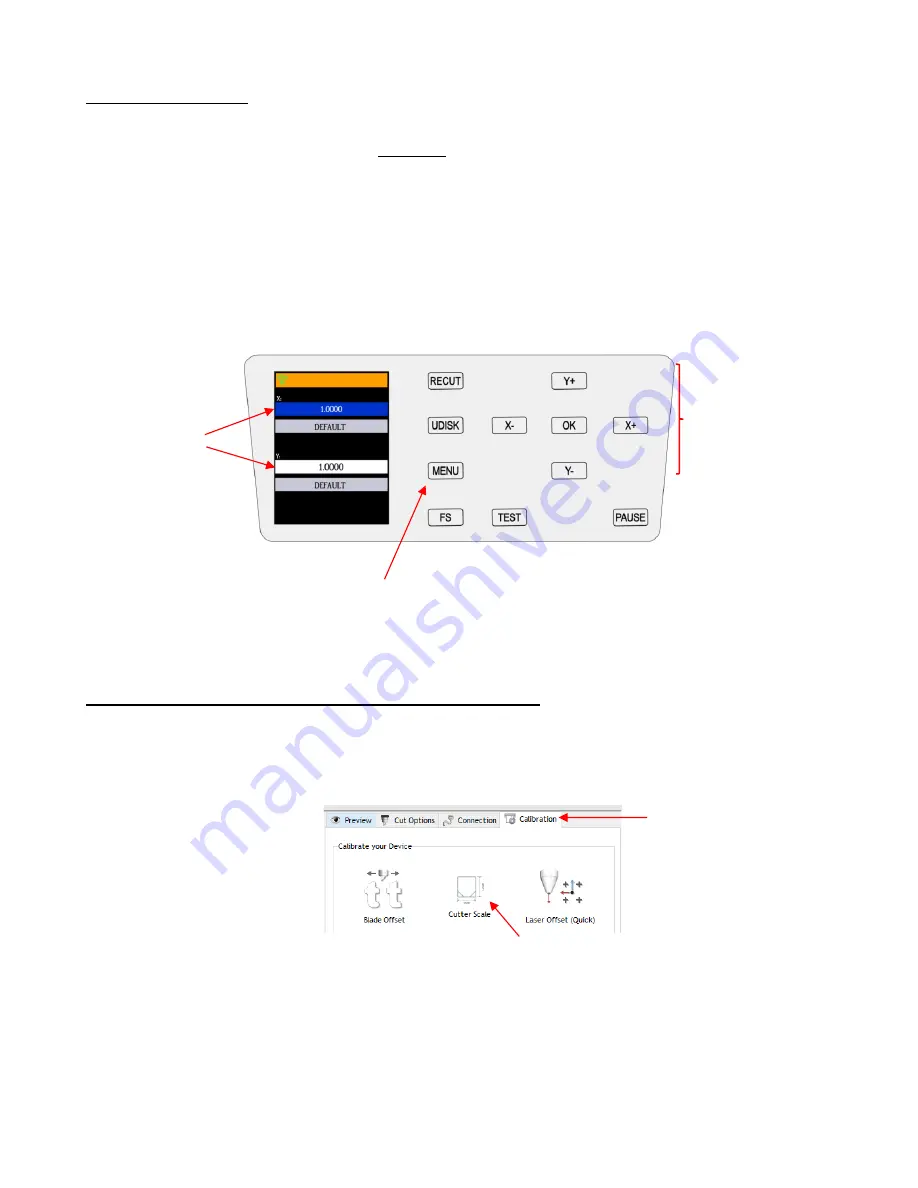

SignMaster has a built-in resolution routine which can be used to easily perform this calibration:

Go to the

Vinyl Spooler

window and select the

Calibration

tab.

Click on the

Cutter Scale

icon:

A new window opens where you can enter the dimensions of a square or rectangle to draw with the test

pen. It is highly recommended that the dimensions be at least 200 mm. Note that in the current version

of SignMaster, the display in this window is always in inches. However, you can enter values in mm by

typing in “mm” after the number as shown:

1. Select the

Calibration

tab

2. Click on the

Cutter Scale

icon

Initially, both

X

and

Y

should be

set to 1.0000

After setting new

Scale

values,

press

MENU

Y- / Y+:

Move

up/down the

menu

X- / X+:

Change

Scale

values