SJ 46A & SJ 46AJ

December 2007

Page 67

TM

Section 2 - Operation

Tables

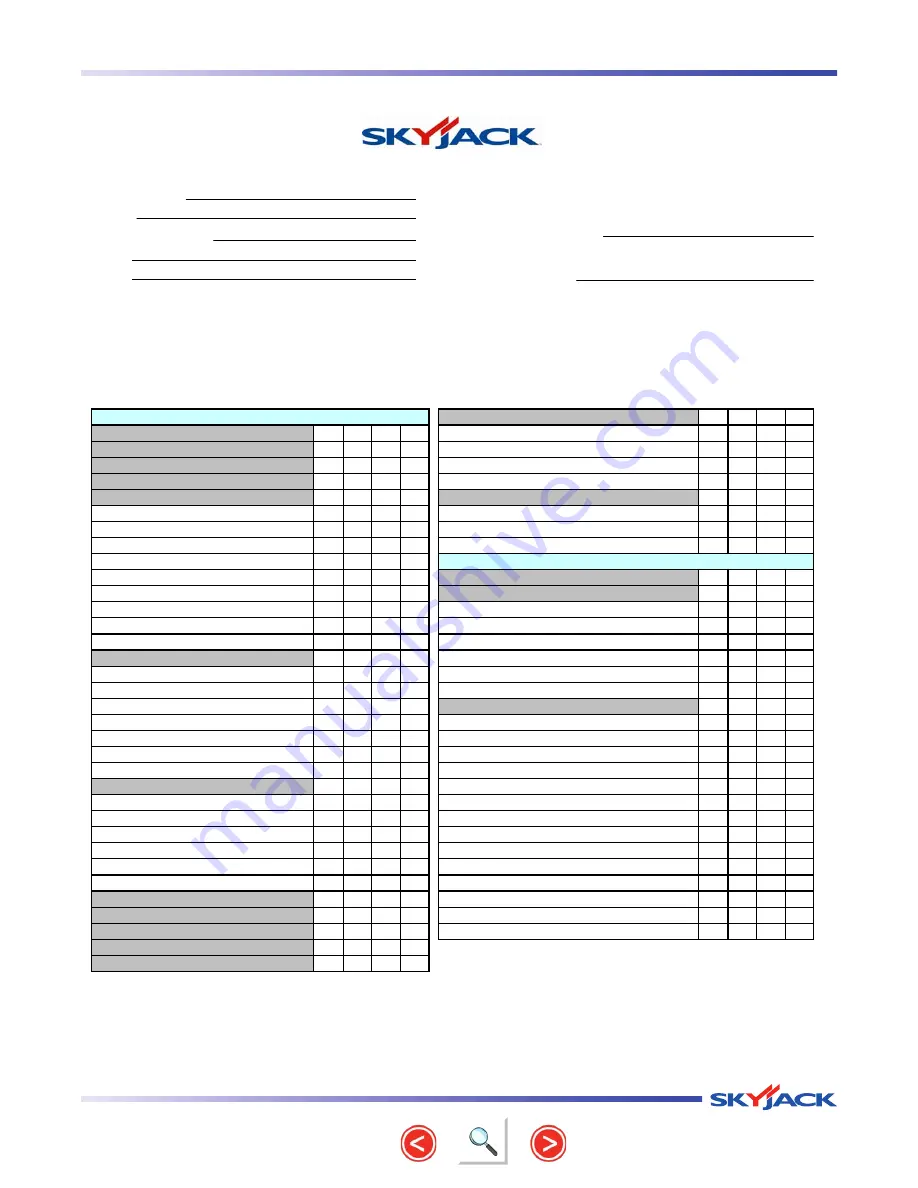

Table 2.8 Operator’s Checklist

INSPECTION FREQUENCY

P

F

R

NA

High Pressure Filter

Hydraulic Pumps

Function Tests

Muffler and Exhaust

Engine Pivot Tray

Engine Oil Level

Engine Air Filter

Fuel Leaks

60643AB-ANSI

Test Oscillating Axles

Engine Compartment

Visual and Daily Maintenance Inspections

- REPAIRED

Labels

Electrical

Limit Switches

Hydraulic

Time:

- PASS

DAILY

- FAIL

FREQUENTLY

As each item is inspected, check the appropriate box.

- NOT APPLICABLE

BI-ANNUALLY

ANNUALLY

OPERATOR'S CHECKLIST

Each item shall be inspected using the the appropriate section of the Skyjack operating manual.

Serial Number:

Model:

Hourmeter Reading:

Operator's Name (Printed):

Date:

Operator's Signature:

Steer Cylinder Assembly

Base

Test Steering

Test Driving Function

Wheel/Tire Assembly

Platform Assembly

Rotary Actuator

Manuals

Tie Rod

Test Driving Speed

Test Emergency Power

Test Horn

Test Brakes

Control Compartment

Test Platform Emergency Stop

Test Footswitch

Test Engine Enable Switch

Platform Control Console

Oscillating Cylinder Assembly

Emergency Power Unit

Drive Axle

Test Brakes

Test Manual Platform Leveling

Test Differential Lock Switch

Main Power Disconnect Switch

Test Emergency Power

Test Base/Off/Platform Switch

Test Platform Emergency Stop Light

Battery

Hydraulic Tank

Brake and Main Manifolds

Base Control Console

Hydraulic Oil

Turret Transportation Lock

Fuel Tank

Fuel Leaks

Battery Warmer/Hydraulic Oil Heater (If Equipped)

Work Light (If Equipped)

Flashing Amber Light (If Equipped)

Test Base Emergency Stop Light

Test Base Emergency Stop

Test Function Enable Switch & All Boom Functions

Test Platform Self-leveling

Jib (If Equipped)

Boom

Special Options

Test Main Power Disconnect Switch

Base Control Console

Platform Control Console

Cylinders

Wear Pads

Hoses

Power Track

Note:

Make a copy of this page or visit the Skyjack web site:

www.skyjack.com for a printable copy.