Telescopic Boom Series

Models SJ61T & SJ66T

194312

December 2007

Page 11

Section 1 - Scheduled Maintenance

Service and Maintenance

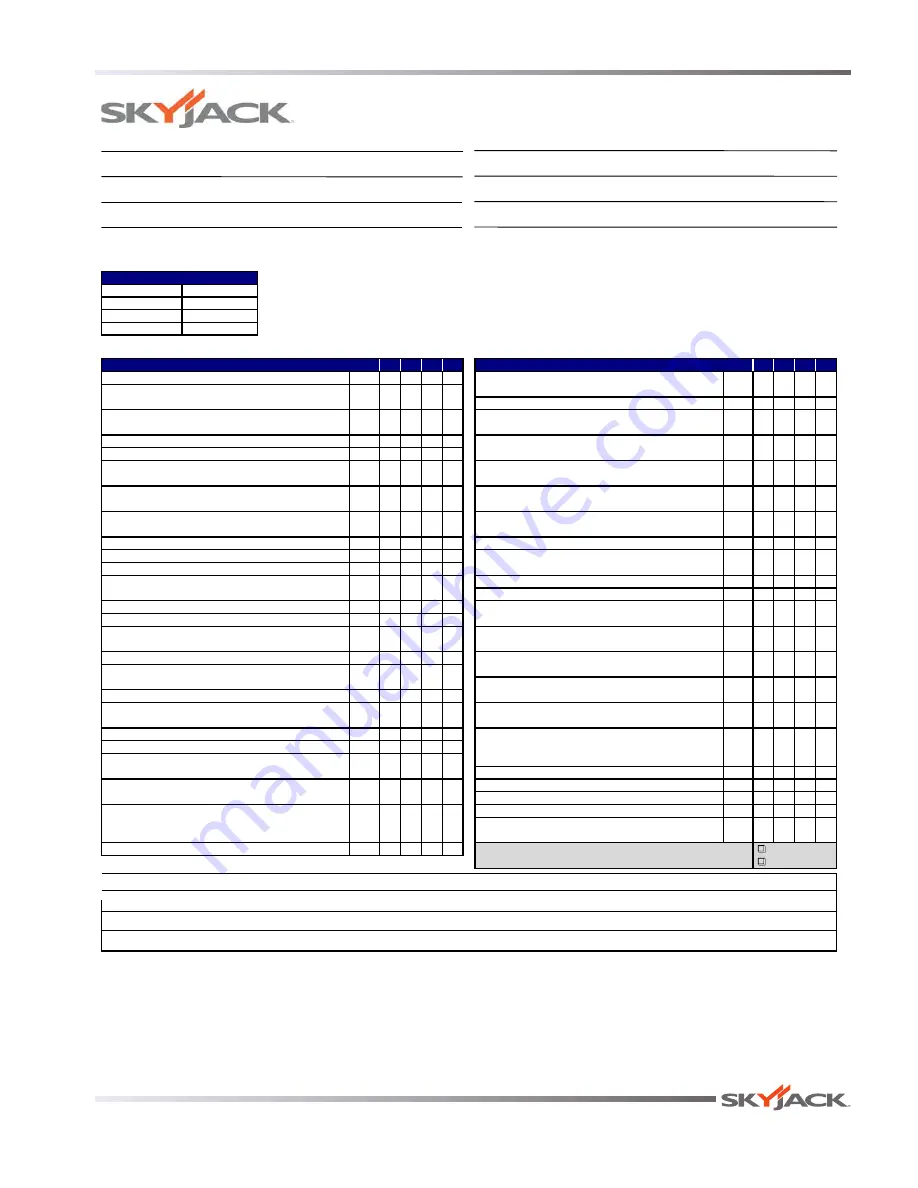

Table 1.2 Pre-Delivery / Maintenance Inspection

Checklist

Note: Visit skyjack.com for a printable copy of this form.

167834AA

Serial Number:

Product Owner:

Model:

Hourmeter Reading:

Product User:

Date/Time:

PDI

B

P - Pass

Frequent

B

F - Fail

Annual

B + C

R - Repaired

Additional

*

N/A - Not Applicable

Items for Inspection

P F R

N/A

Items for Inspection

P F R

N/A

B, C

B

B

B

B, C

B

B

B, C

B

B

B

B

B, C

B, C

B

*, B

B

B

B

B

B, C

Owner: ________________________________________________ / _____________________________________________ / ___________________________________________________

Print Name

Signature

Date (DD/MM/YY)

User: _________________________________________________ / _____________________________________________ / ___________________________________________________

Print Name

Signature

Date (DD/MM/YY)

Inspection Type Schedule

B

B

B

Steer Cylinder Assembly. Secure & no missing parts.

Tight fittings and hoses & no leaks.

Check the appropriate box as each item is inspected. If an item is found to be not acceptable, please describe the issue in the comments box provided.

Refer to skyjack.com for the latest service bulletins.

Ensure Annual Inspection has been completed within the

last 13 months.

Labels. In place, secure & legible.

Limit Switches. Secured & no obstructions or damage.

Battery. No damage, tight connections, adequate fluid

levels. Clean terminals and cable ends.

B

Articulating Booms & Telescopic Booms

Pre-Delivery/Maintenance Inspection Checklist

B, C

B

Cylinders. Secure & no damage or leaks.

Platform Control Console. Switches in neutral position &

secure. No damage or missing parts.

Platform Assembly. No damage or missing parts.

B

C - Perform Scheduled Maintenance Inspections every year. For further details refer to Service & Operating Manuals.

* - Perform time sensitive maintenance intervals. Refer to the Service Manual.

B - Perform PDI prior to each delivery or Frequent Inspections every 3 months or 150 hrs. For further details refer to Service

& Operating Manuals.

Use this form for Pre-Delivery Inspections (PDI) prior to each rental, lease or sale, or as a guide for all Frequent Inspections and Annual Inspections. Refer to the

applicable Operating and Service Manuals for inspection details (eg. Visual Inspection and Function Tests, Torque Specs., Engine Oil, Chain Inspection Intervals,

etc.).

Fuel Tank. Filler cap is secure & no damage or leaks.

Pins & Bushings. No damage/wear, or loose or missing

parts.

B

B

B, C

Oscillating Cylinder Assembly. Secure & no missing

parts. Tight fittings and hoses & no leaks.

Main Power Disconnect Switch. Cables secure & in

working order.

B

Base Weldment. No cracks or deformation.

Brake & Main Manifolds. Tight fittings and hoses & no

leaks. Tight wire connections.

B, C

B

B

Steer Linkage. No damage/wear or missing parts.

Rotary Actuator. No damage or missing parts. Tight

fittings, hoses and bolts & no leaks.

Riser. Secure & no damage/deformation or missing parts.

Engine Fuel Filter. No damage, missing parts or leaks.

PASS

FAIL

Comments:

Function Tests

(Refer to your corresponding Serial #'s Operating

Manual for information on running these tests.)

Wheel/Tire Assembly. Check all tires for damage, wear

& proper alignment. Lug nuts torqued as recommended.

B, C

Engine Pivot Tray. Secure & no damage or missing parts.

Engine Oil. Level in the "safe" zone. Ensure oil change

interval has not been exceeded.

Wear Pads. No damage or missing parts. Bolts tightened.

Engine Fuel Leaks. No damage or leaks from tank,

shutoff valve & hoses and fittings.

B, C

B, C

B

Engine Air Filter. No damage or missing parts.

Jib. No damage or missing parts. Tight hoses and bolts &

no leaks.

Boom. No damage or missing parts. No deformation or

cracks in welds. Tight hoses and bolts & no leaks.

Turret Rotation Gear. No damage or missing parts.

Rotary Manifold. Tight fittings & hoses, & no leaks.

High Pressure Filter. Secure & no damage or leaks.

Hydraulic Pumps. Tight fittings, hoses & bolts. No

damage, missing parts or leaks.

Muffler and Exhaust. Secure & no damage.

Raillings and Gate. Secure & no damage or missing parts.

B

The undersigned confirms that all areas listed have been inspected, and any and all discrepancies have been brought to the attention of the owner. Furthermore, the

undersigned confirms that all discrepancies have been corrected prior to using this machine.

Emergency Power Unit. Tight fittings and hoses & no

leaks. Tight wire connections & no damage or missing

parts.

B

Control Cables and Hoses. No damage or missing parts.

No spring gaps. Ensure Inspection Interval has not been

exceeded.

*, B

Cable Carrier. No damage or missing parts.

Special Options and Approved Attachments. Secure &

no damage or missing parts.

Base Control Console. Switches in neutral position & no

damage or missing parts.

Fuel Tank Leaks. Tight fittings and hoses & no damage or

leaks.

B

Hydraulic Filter. Secure & no damage, missing parts or

leaks.

B, C

Manuals & Required Documents. In storage box, in

good condition & legible.

B

Lanyard Attachment Anchorage. Attachment rings

secure & no damage.

B

Drive Axle. Secure & no missing parts. Tight fittings and

hoses & no leaks.

Turret Transportation Lock. Unlocked & no damage or

missing parts.

Swing Drive Motor. Tight fittings, hoses & bolts. No

damage, missing parts or leaks.

Hydraulic Tank. Filler cap secure & no damage or leaks.

Hydraulic Oil. Level between min. & max. marks.

Summary of Contents for SJ61T

Page 1: ...TELESCOPIC BOOMS MODELS SJ61T SJ66T 194312AE February 2017 SERVICE MANUAL...

Page 42: ...Page 42 December 2007 Telescopic Boom Series Models SJ61T SJ66T 194312 Notes...

Page 230: ...Page 230 December 2007 Telescopic Boom Series Models SJ61T SJ66T 194312 Notes...

Page 231: ......

Page 232: ...www skyjack com P litelig lift l sninger av folk som bryr seg...