161

SJ82 T, SJ86 T

229040ABA

Section 5 – Procedures

5.1 General

The following information is provided to assist you in

the use and application of servicing and maintenance

procedures contained in this chapter.

NOTE

The illustrations shown in this manual are for

instructional purposes only. The models and

components shown may appear somewhat

different from those on your actual MEWP.

5.1-1 Safety and Workmanship

Your safety, and that of others, is the first

consideration when engaging in the maintenance of

equipment. Always be conscious of weight. Never

attempt to move heavy parts without the aid of a

mechanical device. Do not allow heavy objects to rest

in an unstable position. When raising a portion of the

equipment, ensure that adequate support is provided.

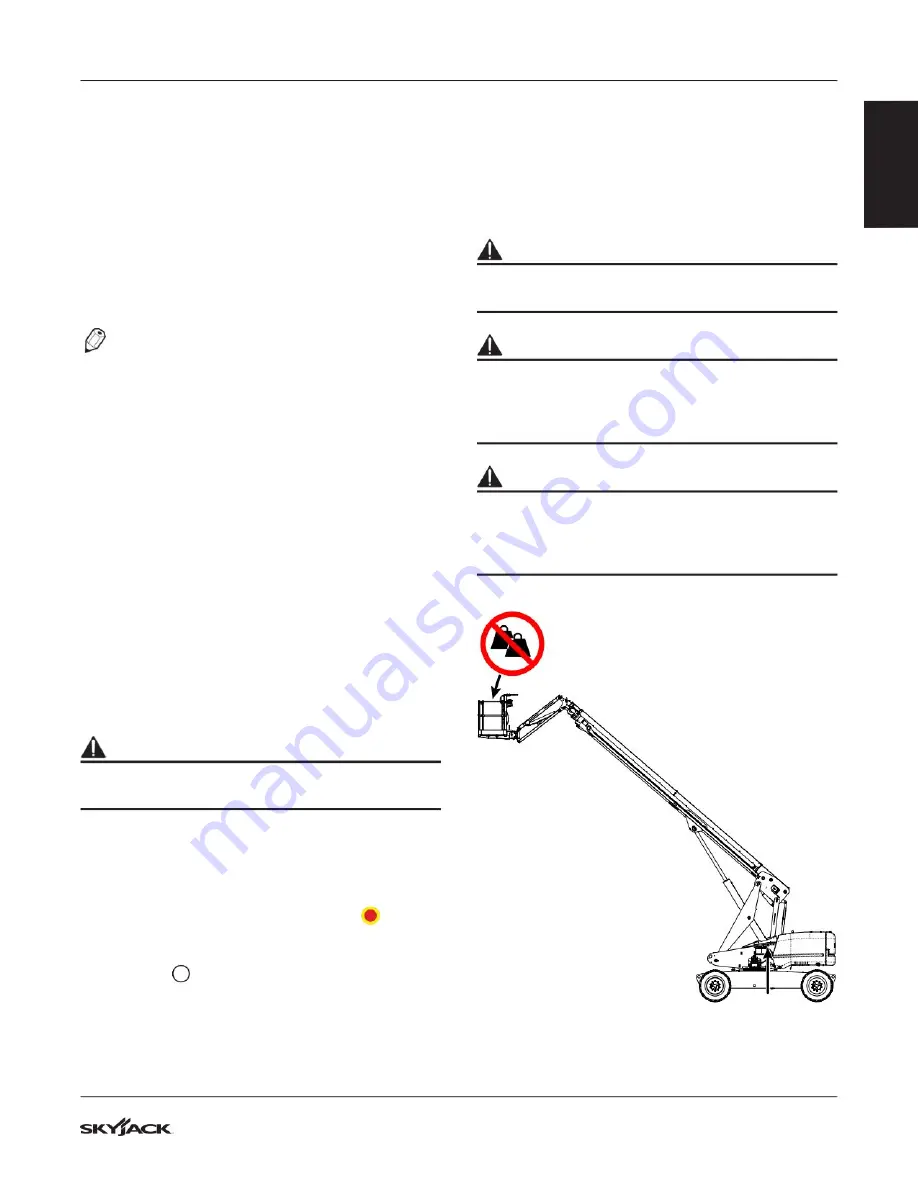

Before performing routine maintenance underneath

the boom, support it using a maintenance support or

equivalent supporting device. Refer to Figure 01 and

5.1-2 How to Install the Boom Maintenance Support

.

Contact Skyjack Parts to order a maintenance

support.

WARNING

Remove all material and personnel from the

platform while using the maintenance support(s).

1.

Park the MEWP on a firm, level surface.

2.

Retract and lower the boom and platform until

the MEWP is in the stowed position.

3.

Turn the engine off.

4.

Pull out the emergency stop buttons

on the

base controls and on the platform controls.

5.

Turn the battery disconnect switch to the off

position

.

After completing any procedure which involves

modifying, adjusting, or replacing any hydraulic or

electrical components, perform all of the function tests

given in your unit’s Operating Manual.

WARNING

Make sure you maintain three points of contact

when mounting and dismounting the platform.

WARNING

Do not operate any platform controls without the

proper fall protection secured to the designated

location in the platform. Failure to do so could

result in death or serious injury!

WARNING

Make sure there are no people or obstructions in

the test area, and there is sufficient space for the

boom and drive functions required for the given

procedures.

106 757 N

24,000 lbf

Figure 01

Support location

To

order

go

to

Discount-Equipment.com