181

SJ82 T, SJ86 T

229040ABA

Boom

Section 5 – Procedures

5.4 Boom

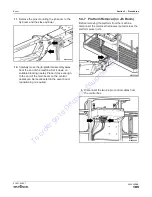

5.4-1 Check Wear Pads

1.

Ensure the MEWP is on a firm level surface and

is in the stowed position.

2.

Start the engine from the base control console.

3.

Raise the main boom to a comfortable working

height (chest high), and then extend fly boom

approximately 1 ft (30 cm).

4.

Measure the thickness of each wear pad, and

replace wear pad if it is less than 7/16 inches

(11mm).

5.

If the wear pad is within the specified thickness,

shim it as necessary.

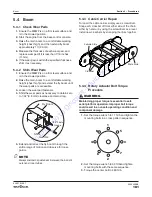

5.4-2 Shim Wear Pads

1.

Ensure the MEWP is on a firm level surface and

is in the stowed position.

2.

Raise the main boom to a comfortable working

height (chest high) and extend the fly boom until

the wear pads are accessible.

3.

Loosen the wear pad fasteners.

4.

Shim the wear pads as necessary to obtain zero

to 1/32”(0.8 mm) clearance and zero drag.

Fly Boom

Shim

1/32” Feeler

Gauge

Wear Pad

5.

Extend and retract the fly boom through the

entire range of motion and observe for loose

points.

NOTE

Always maintain squareness between the boom’s

outer and inner tubes.

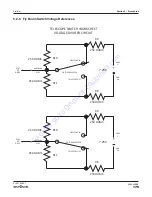

5.4-3 Cable Carrier Repair

To repair the cable carrier, simply use a screwdriver.

Snap each crossbar off from either side of the chain,

either by hand or by using the screwdriver as a lever.

Install new crossbars by snapping the links together.

Crossbar

Male Side

Female Side

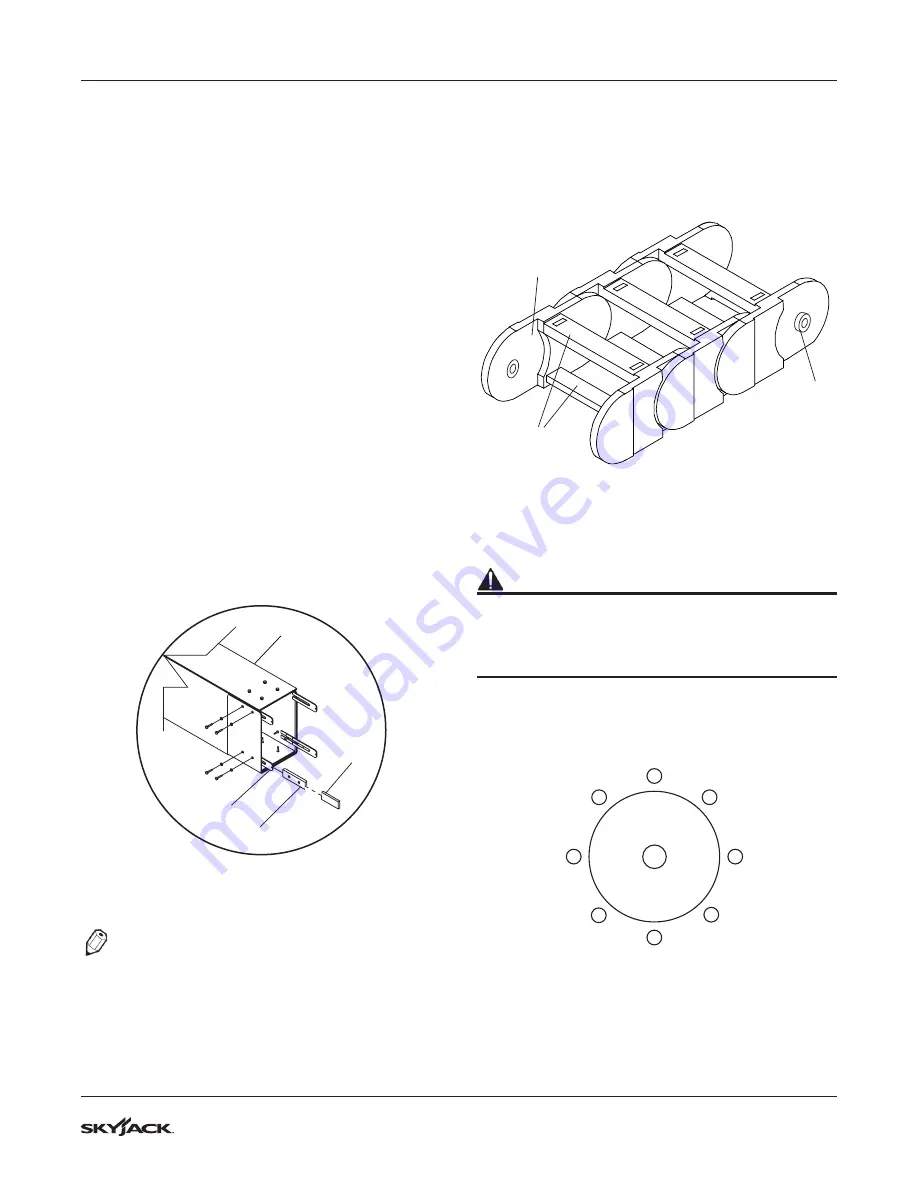

5.4-4 Rotary Actuator Bolt Torque

Procedure

WARNING

Maintaining proper torque is essential to safe

aerial platform operation. Improper bolt torque

could result in an unsafe operating condition and

component damage.

1.

Set the torque wrench to 17 ft-Ib and tighten the

mounting bolts in a cross pattern sequence.

1

5

3

7

2

6

4

8

2.

Set the torque wrench to 35 ft-Iband tighten

mounting bolts with the same sequence.

3.

Torque the center bolt to 480 ft-lb.

To

order

go

to

Discount-Equipment.com