194

SJ82 T, SJ86 T

229040ABA

Section 5 – Procedures

Boom

5.4-16 Extension Cylinder and Wire Rope

Replacement

Inspecting the cable assembly and extension cylinder

for wear requires completely removing them from

inside the boom assembly. Adequate space must be

provided to do so. See

5.4-20 Wire Rope Inspection

.

CAUTION

Risk of personal injury or equipment damage if

repositioning boom during this procedure. Use

base controls with auxiliary power (engine off) to

reposition safely.

CAUTION

Risk of personal injury or equipment damage.

Always use suitable lifting equipment and safe

rigging practices when performing the following

procedures.

IMPORTANT

When operating on auxiliary power, do not

operate more than one function at a time to avoid

overloading the 12-volt auxiliary pump motor.

IMPORTANT

Prevent hydraulic system contamination

by capping all hydraulic connections after

disconnecting. Sample warning text.

5.4-17 Extension Cylinder and Cable

Assembly Removal

▪

Place the boom in a horizontal (0°) position.

▪

Shut down the machine.

1.

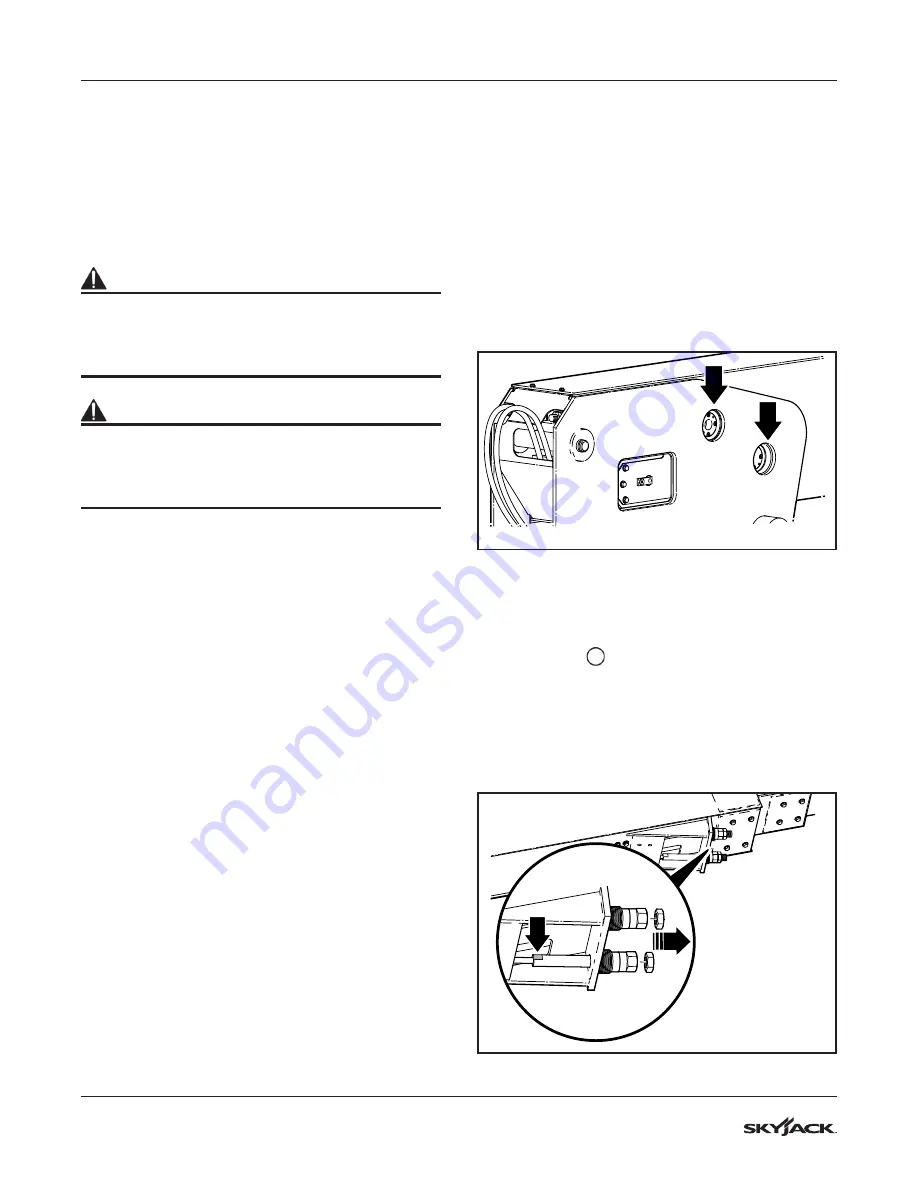

Extend/retract the boom to align the flange pins

with the holes in the side of the main boom. The

lower flange pins connect the wire rope terminal

assembly to the fly boom. The upper flange pins

connect the cylinder base to the mid boom.

M62264AA

2.

Place the machine in the proper shut down

position, parked on level ground. Make sure the

e-stops are pushed in and the key is off. Turn the

main disconnect switch to off position. Lock out

the switch

.

3.

Loosen the wire ropes on the platform end of

the machine first. Remove the jam nut, then use

the flat on the end of wire rope anchor to hold it

while backing off the main nut. Leave the main

nut on the wire rope anchor about one full nut

thread.

M62265AA

To

order

go

to

Discount-Equipment.com