200

SJ82 T, SJ86 T

229040ABA

Section 5 – Procedures

Boom

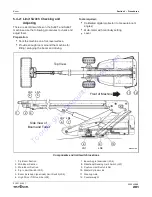

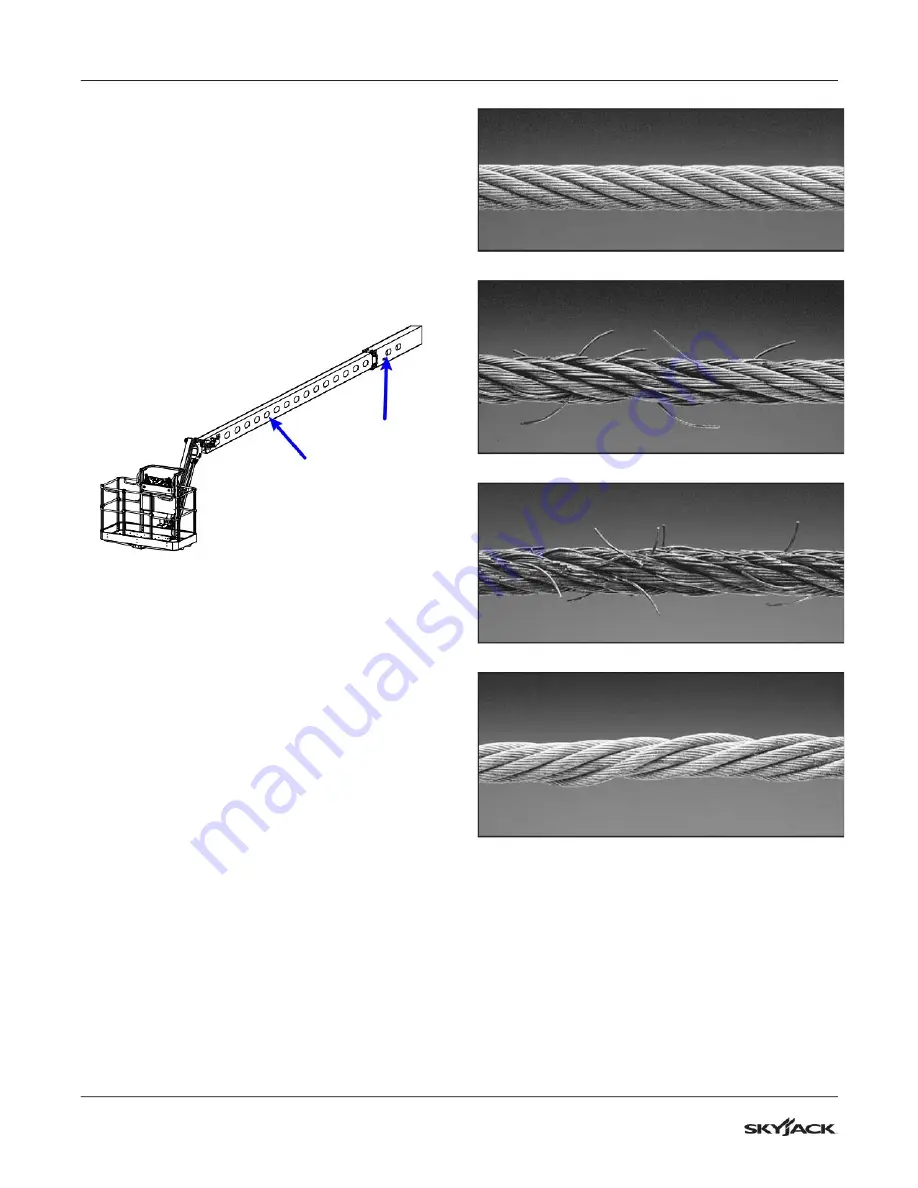

5.4-20 Wire Rope Inspection

▪

Perform a visual inspection of the wire ropes

annually. Check for wear or damage. Make sure

wire ropes are tensioned correctly. See

5.4-19

Proper Wire Rope Tension

.

▪

A visual inspection can be performed by fully

extending the boom, and inspecting the cables

through the sight holes along the boom arm.

▪

Perform a full inspection of the wire rope

assembly every ten years. To perform a full

inspection, the extension cylinder and wire rope

assembly must be fully removed from the boom

assembly. See

5.4-17 Extension Cylinder and

Cable Assembly Removal

.

IMPORTANT

Perform a full inspection of the wire ropes at the

start of the 10th year of wire rope life. They must

be inspected every 2 years if not replaced at that

time.

Perform a visual inspection annually.

If a wire rope needs replacement, the entire wire rope

assembly must be replaced immediately.

Check wire ropes for wear or damage. A wire rope

with broken wires, severe corrosion, excessive stretch,

deformed strands, variations in diameter (necking),

or any change from its normal appearance, must be

replaced.

Cable in Good Condition

Cable with Broken Wires

Cable with Rust

Cable with Necking

Sheave Inspection

Check sheaves (pulleys) for wear or damage, For

example, wobble (tilt), cracks, loose on pin, or

excessive noise during operation.

Sheave Pins Inspection

Check for loose or missing sheave (pulley) pins.

To

order

go

to

Discount-Equipment.com