TM

ZB12032

December 2007

Page 33

Visual and Daily Maintenance Inspections

Section 2 - Operations

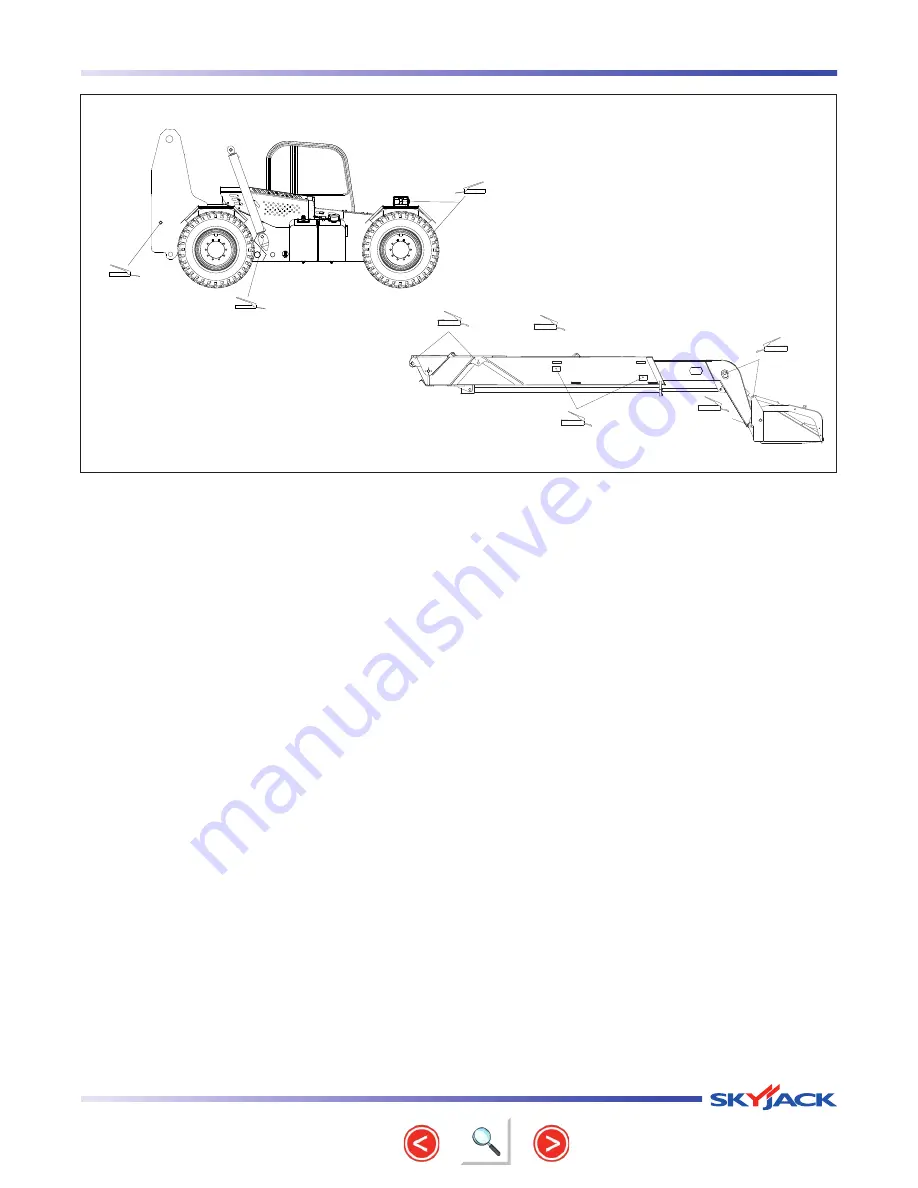

Grease Points on Frame

1. Ensure telehandler is on a firm level surface

and is in stowed position.

2. Locate grease fittings (refer to label inside

operator’s cab) and pump grease in the

following:

axle pivot bearings (front and rear)

-

axle lock cylinder (top and bottom)

-

lift cylinder (top and bottom, both

-

sides)

frame level cylinders (top and bottom)

-

outrigger pins

-

slave cylinders (top and bottom)

-

3. Using a creeper, slide under the frame to

locate grease fittings and pump grease in

the following:

drive shaft U-joint (front and rear)

-

slip joint on drive shaft (front and rear)

-

Grease Points on Boom Assembly

1. Ensure telehandler is on a firm level surface

and is in stowed position.

2. Locate grease fittings (refer to label inside

operator’s cab) and pump grease in the

following:

main boom pivot bearing pins

-

retract chain rollers

-

hose rollers

-

extension chains and rollers

-

slide pads

-

attachment tilt cylinders (top and

-

bottom)

attachment pivot bearings

-

Summary of Contents for ZB12032

Page 1: ...MODELS ZB12032 Operating Manual ZOOM BOOM Telehandlers Part No 402286AB A September 2010...

Page 6: ...TM Page 6 December 2007 ZB12032 Notes...

Page 16: ...TM Page 16 December 2007 ZB12032 Notes...

Page 69: ...TM Page 72 December 2007 ZB12032 Notes...

Page 70: ...TM ZB12032 December 2007 Page 73 Notes...

Page 71: ...TM Page 74 December 2007 ZB12032 Notes...

Page 73: ...Reliable lift solutions by people who care www skyjack com...