MAT-MA-0035_GB SKYTAC

Version as of: 13/02/2018

page 26 of 37

12

PRODUCT DESCRIPTION

Climbing protection rail without rungs TAC-0020

The climbing protection rail without rungs can be retrofitted to existing ladder systems with

a rung spacing of 280 - 300mm and a rung size of up to 30mm diameter (rung bracket) or a

rectangular cross section of 30mm deep and maximum 50mm high (mounting disc).

As with the climbing protection ladder, an end stop must be mounted at each exit point on

the start and end of the ascent route, respectively.

End stops, exit devices, and other accessories are the same as for the climbing protection

ladder. The rest platform is offered with its own holder for aluminium ladders. (TAC-0140-

AL)

Safety Information

Due to the lower resistance of aluminium ladders compared with steel, when installing the mounting disc,

the max. tightening torque for fittings must be reduced to 40Nm to avoid damaging the ladder and the disc.

When using the clamping rail TAC 0260-200, a torque of 5 Nm must not be exceeded for aluminium

ladders, otherwise damage to the aluminium rungs can be expected.

This does not apply for the rung bracket TAC-0190, the butt connector TAC-0040/TAC-0040-190 and the

rest platform TAC-0140-AL, since in this case the tightening torque for attachment to the climbing

protection rail is to remain at 71Nm.

Caution:

Never install a bolt in an open slot in the climbing protection rail

!

12.1 Installation of the climbing protection ladder

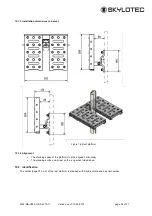

12.1.1 Installation kit

Climbing protection rail segments in various lengths.

Each rail segment is marked with a label that has a serial number welded onto it.

Various mounting options: Rung bracket TAC-0190, mounting disc TAC-0030 or clamping

rail TAC-260-200.

At least 1 per ladder segment, maximum distance of 1200 mm between the fasteners

(except for flange extension brackets in wind turbines).

One coupling piece per joint TAC-0040/ TAC-0040-190

One end stop at each entry and exit point TAC-0050

One end stop TAC-0060 in the upper ladder segment if the runner can remain in the ladder

system.

One information sign per ladder system.

Fastening material:

Mushroom head bolts similar to DIN 603-M12-8.8, self-locking hexagon nuts DIN 985 with

non-metallic locking, D = 13 washers for the attachment of mounting brackets, connecting

plate, insert lock and end stop

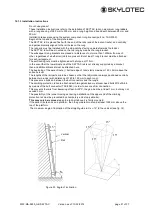

12.1.2 Tools needed for installation:

1x Torque wrench SW 19

1x Hacksaw or angle grinder with cutting disc

1x Crosscut saw

1x Flat file for deburring (maximum 35 mm wide)

Zinc spray in accordance with DIN EN ISO 1461 to coat the cut surfaces

PPE

At least 2 persons are required for installation