E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

01/09/2020

4/18

SAFETY

p. 2

TABLE OF CONTENTS

p. 4

OVERVIEW PROFILES AND

SUPPLIES

p. 5

SAFETY AND WARNINGS

p. 6

PRIOR INSPECTION

p. 6

ASSEMBLY SEQUENCE OF FIXED AND

OPENING PARTS

p. 8

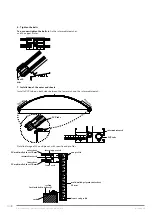

OUTLINE DRAWING CINTRALUX

ALU EP10/10 – FIXED PARTS

p. 8

ASSEMBLY SEQUENCE OF FIXED PARTS p. 9

ASSEMBLY CINTRALUX ALU EP10/10 –

FIXED PARTS

p. 9

INSTALLATION OF THE END PROFILE

AND LATERAL PROFILE

p. 9

INSTALLATION OF THE LOWER ARCH

PROFILES AND THE INNER SHEETS

p. 11

INSTALLATION OF THE INTERMEDIATE

ARCHES

p. 12

INSTALLATION OF THE OUTER

SHEETS

p. 12

INSTALLATION OF THE UPPER

ARCHES

p. 13

TIGHTEN THE BOLTS

P. 14

INSTALLATION OF THE OUTER END

SHEETS

P. 14

FINISH WITH ALUMINUM STRIPS

P. 16

CHECK THE ARCH TENSIONS

P. 16

FINISH THE SEAMS OF THE LATERAL

PROFILES

P. 17

CONTINUE FINISHING THE OPENING

PARTS, IF ANY

P. 17

MAINTENANCE

P. 17

SNOW AND WIND LOAD

P. 17

DISCLAIMERS

P. 17

Table of contents