20/11/2020

17/88

E_MH_Installation_instructions_Skylux_Climax

u

Nearly all silicone products affect

the polymethyl methacrylate or poly-

carbonate sheets. Purchase silicone

types that are safe for polymethyl

methacrylate or polycarbonate pro-

ducts (guarantee certificate).

u

The fumes from this putty may

never evaporate in the slots of the

sheet. The ventilation openings as well

as the sides of the end profiles may

not be closed off. The silicone should

always be allowed to release fumes

freely.

u

Some seals contain softening agents

(as used in certain types of rubber,

PVC, polyurethane, etc.) that may

cause small cracks. Use only approved

seals.

u

Do not use black or dark-coloured

seals to prevent heat accumulation.

u

A lead slab may be placed on the

seals but may not rest against the

sheets.

u

Some paints, varnishes and wood

protectors affect the polymethyl

methacrylate or polycarbonate sheets.

Never use lubricants to put the seals

into the profiles.

u

Never spray insecticide directly on

to the sheets. Synthetic sheets can be

damaged by these products.

2. SILICONE, SEALS AND

WOOD PROTECTORS

u

Observe the safety instructions

that apply to work on roofs.

Polycarbonate sheets: Very

IMPORTANT! The side which is

protected against UV radiation

must always be installed facing

the exterior or the sky. The “sun

side” is indicated on the protec-

tion film.

u

The plastic tape or the provisional

aluminium tape will only ensure the

sheets are free from dust while being

shipped. These should be removed!

Adjusted aluminium tape or end pro-

files must be used.

u

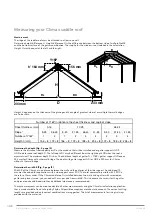

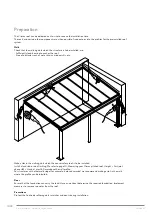

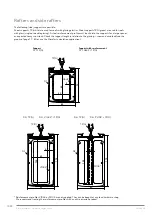

The load-bearing structure must

be strong and stable. (See the regu-

lations that apply to the timber and

metal construction industry.) Cross

supports may be required depending

on the type of sheet used. Only spe-

cific maximum lengths may be used

without a cross support for each

type of sheet taking into account

the loads of 500 N/m

2

or 750 N/

m

2

, respectively (see the technical

plastic sheets information sheet).

u

Pergotop/Pergotop-soft sandwich

panels are only adapted in combina-

tion with Skylux screwable clips.

u

Heat accumulation: the top side

of the load-bearing structure that is

turned towards the sheets must be

WHITE reflective.

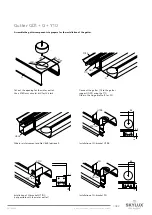

4. INSTALLATION

Synthetic sheets can expand or shrink

when there are temperature fluctua-

tions. The following tips should be

taken into account:

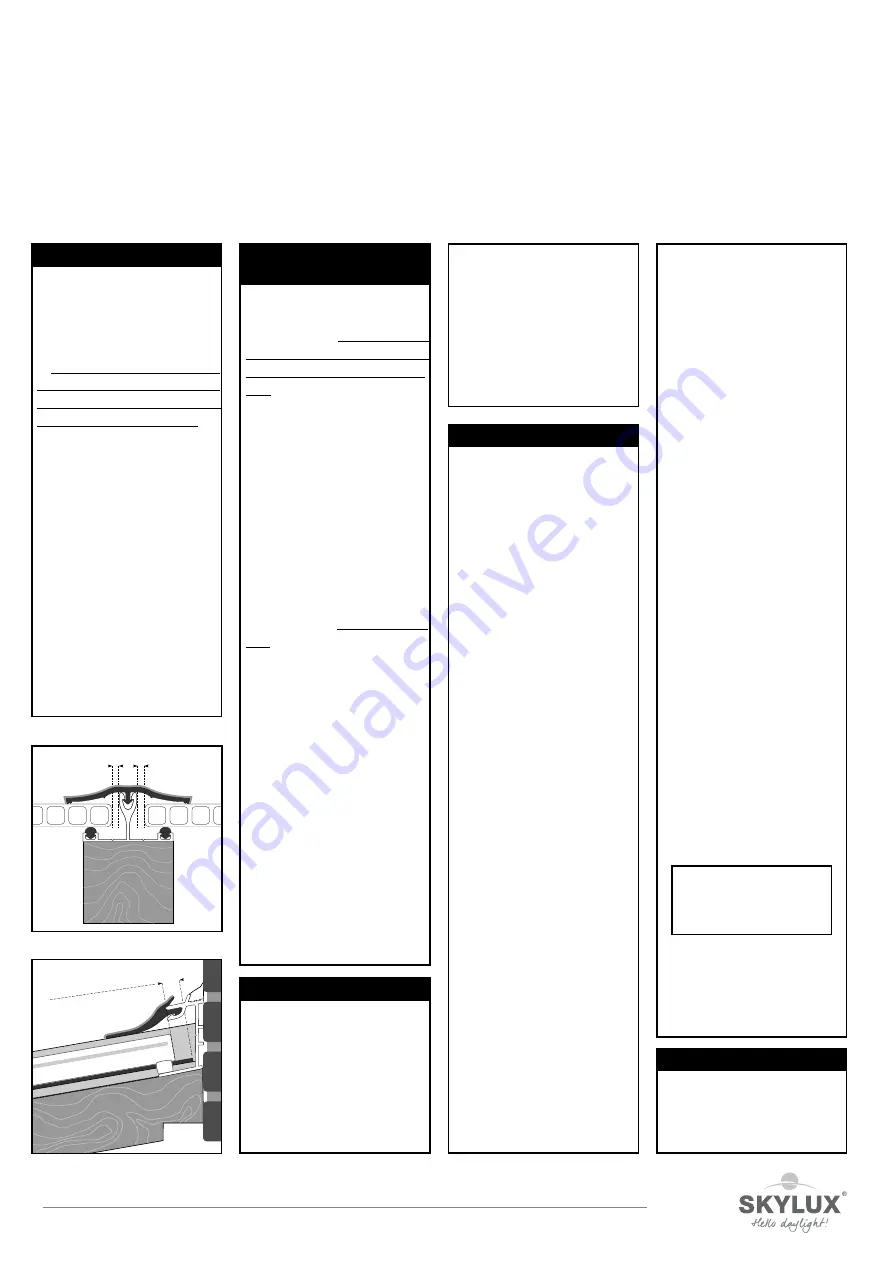

u

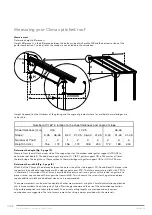

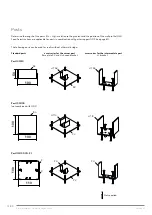

Ensure there is 5 mm clearance

lengthwise for each sheet meter and

ensure there is 10 mm clearance

(5 mm on each side) widthwise, for

example, a 3000 mm sheet must

have a clearance lengthwise of 1.5 cm.

u

Never block the sheet lengthwise

or widthwise. Always ensure sufficient

clearance

.

u

Never stick the sheet using silicone

(even when it does not damage syn-

thetic materials). It would prevent the

expansion and shrinkage of the sheets.

u

The sheet is blocked at the bot-

tom end to prevent it from sliding. The

clearance must, therefore, be pro-

vided at the top.

1. CLEARANCE

5 mm 5 mm

u

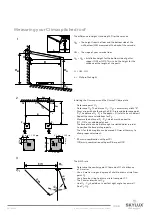

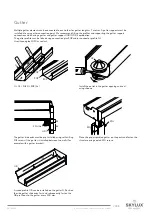

Apply white dispersion paint (diluted

in water or paint without solvents) or use

preferably aluminium tape. Attention:

Let the paint dry after painting the

load-bearing structure! Continue with

the installation of the sheets after the

paint has dried. The synthetic sheets may

NEVER be installed directly on to tim-

ber structures.

u

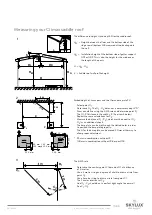

Do not place roof tiles directly on

the sheets! Leave a space of at least

10 mm between the sheets and the

roof covering.

u

Use a special weather stripping (seal

C6) for sealing the opening between

the plate and the gutter beam. Do not

seal using sealant or fill with PU foam.

u

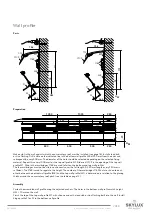

We formally recommend not add-

ing a ceiling under the acrylic sheets

(PMMA). Any used sun blinds or

other finish under the sheets should

be at least 120 mm from the roofing

sheet. These may not have insulation

properties and should have a reflect-

ing colour. The polycarbonate sheets

(PC) do not require any specific pre-

cautions.

u

WIDTH DISTRIBUTION

OF THE SHEETS

:

RECOMMENDED: standard

sheet width with an adapter for the 2

outer sheets. This is especially impor-

tant for the S5P heat-stop sheet.

NOT RECOMMENDED:

in equal sections with sized sheet

widths. Take the standard sheet width

into account. We formally advise

against sizing multiple-layer sheets.

The closed off sides are

one of the factors that

determine the sheet

strength!

u

Follow the installation instructions

provided by the glass manufacturer

when including the installation of

glass!

5. GLASS

u

Clean the sheets annually using

lukewarm rainwater. Dissolve a little

household soap (neutral) in the water

if required (no detergent!!). Never use

solvents or abrasive products.

u

Do not rub dry (may cause

scratches).

u

Simply rinse.

3. MAINTENANCE

Space for expansion

u

Clean the surfaces/profiles min.

1 a year with cold water and a mild

soap. Rinse well with plenty of

water.

Never use solvents or abrasives!

A good cleaning is necessary to

avoid the profiles from growing dull

and dirty by the UV light!

General tips and maintenance instructons

The qualitative and technological level of the multiple layer plastic sheet is high. We provide a few important tips for problem-free

installation. Please pay special attention to the following: Space for expansion/silicone and wooden protection/seals.