8

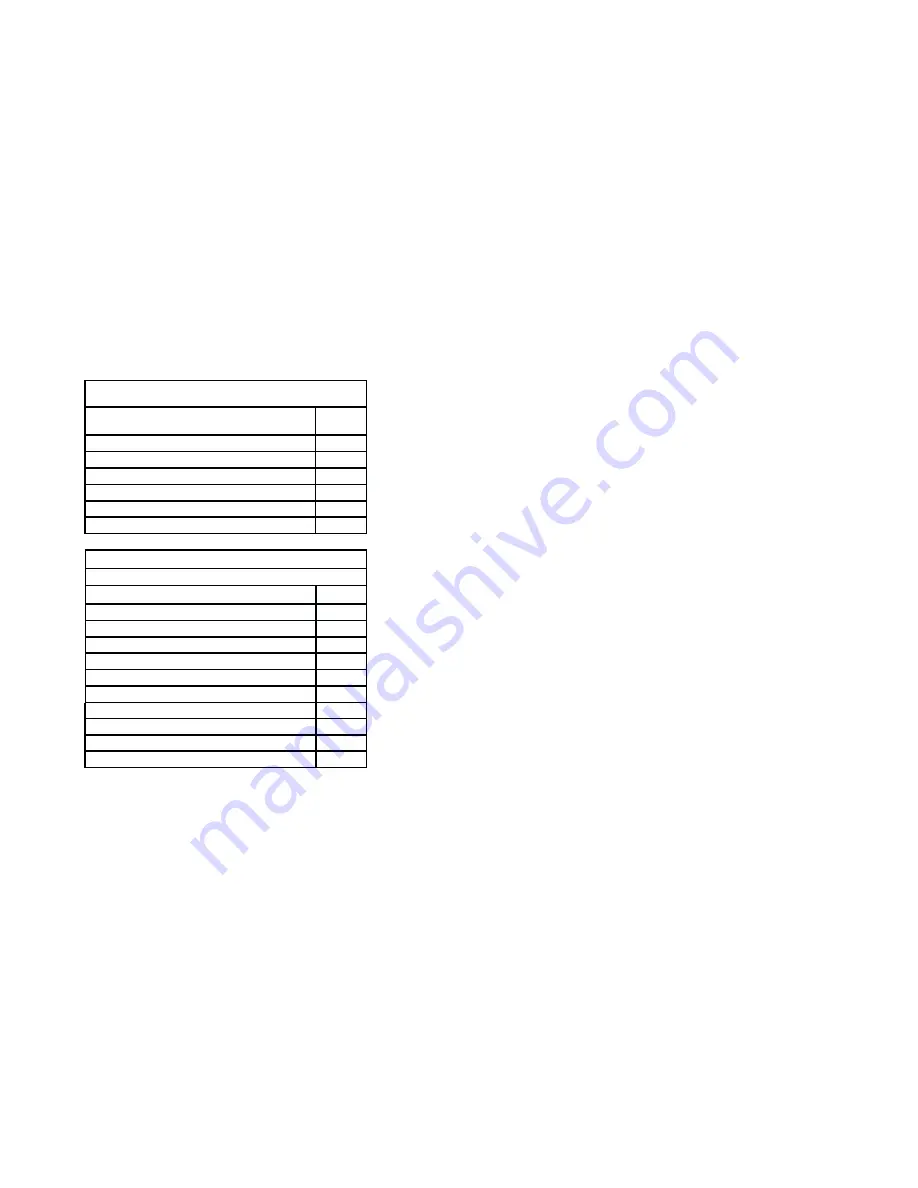

1.5 Plates coming along with the Processor and Op

ti

onal Plates

In the following Table 03 you will

fi

nd the available Plates:

TABLE 03

PLATES COMING ALONG WIT THE EQUIPMENT

NAME

MODEL

SLICER - 1 mm

E1

SLICER - 3 mm

E3

SHREDDER - 3 mm

Z3

SHREDDER - 5 mm

Z5

SHREDDER - 8 mm

Z8

GRATER

V

OPTIONAL PLATES

(SOLD IN SEPARATE)

NAME

MODEL

SLICER - 5 MM

E5

SLICER - 10 MM

E10

DENTED SLICER - 3 MM

EH3

DENTED SLICER - 7 MM

EH7

SLICER SCALLOP CUT - 2MM

W2

SLICER SCALLOP CUT - 3 MM

W3

SLICER SCALLOP CUT - 4 MM

W4

SQUARE SHREDDER (JULIENE) - 2,5 MM

H2,5

SQUARE SHREDDER (JULIENE) - 3 MM

H3

SQUARE SHREDDER (JULIENE) - 7 MM

H7

17

circuits.

The oil reservoirs have to be

fi

lled un

ti

l the indicated level. Check and re

fi

ll if necessary.

4.3 Rou

ti

ne Inspec

ti

on

4.3.1 Advice

When checking the tension of the belts or chains, DO NOT insert your

fi

ngers between the

belts and the pulleys and nor between the chain and the gears.

4.3.2 Precau

ti

ons

Check the motor and sliding or turning parts of the machine in case of abnormal noises.

Check the tension of the belts and chains and replace the set when belts or chains show

signs of wearing.

When checking the tension of belts or chains DO NOT insert your

fi

ngers between belts

and pulleys, nor between the chains and gears.

Check protec

ti

ons and safety devices to make sure they are working properly.

4.4 Opera

ti

on

4.4.1 Warnings

Do not use the machine with long hair that could touch any part of the machine. This might

lead to a serious accident. Tie your hair up well and/or cover it with a scarf.

Only trained or skilled personnel shall operate this machine.

Never touch turning parts with your hands or any other way.

NEVER operate the machine without any original safety devices under perfect condi

ti

ons.

4.5 A

ft

er Finishing The Work

4.5.1 Precau

ti

ons

Always TURN THE MACHINE OFF before cleaning by removing the plug from the socket.

Never clean the machine unless it has come to a complete stop.

Put all the components back to their func

ti

onal posi

ti

ons before turning the machine ON

again.