10

15

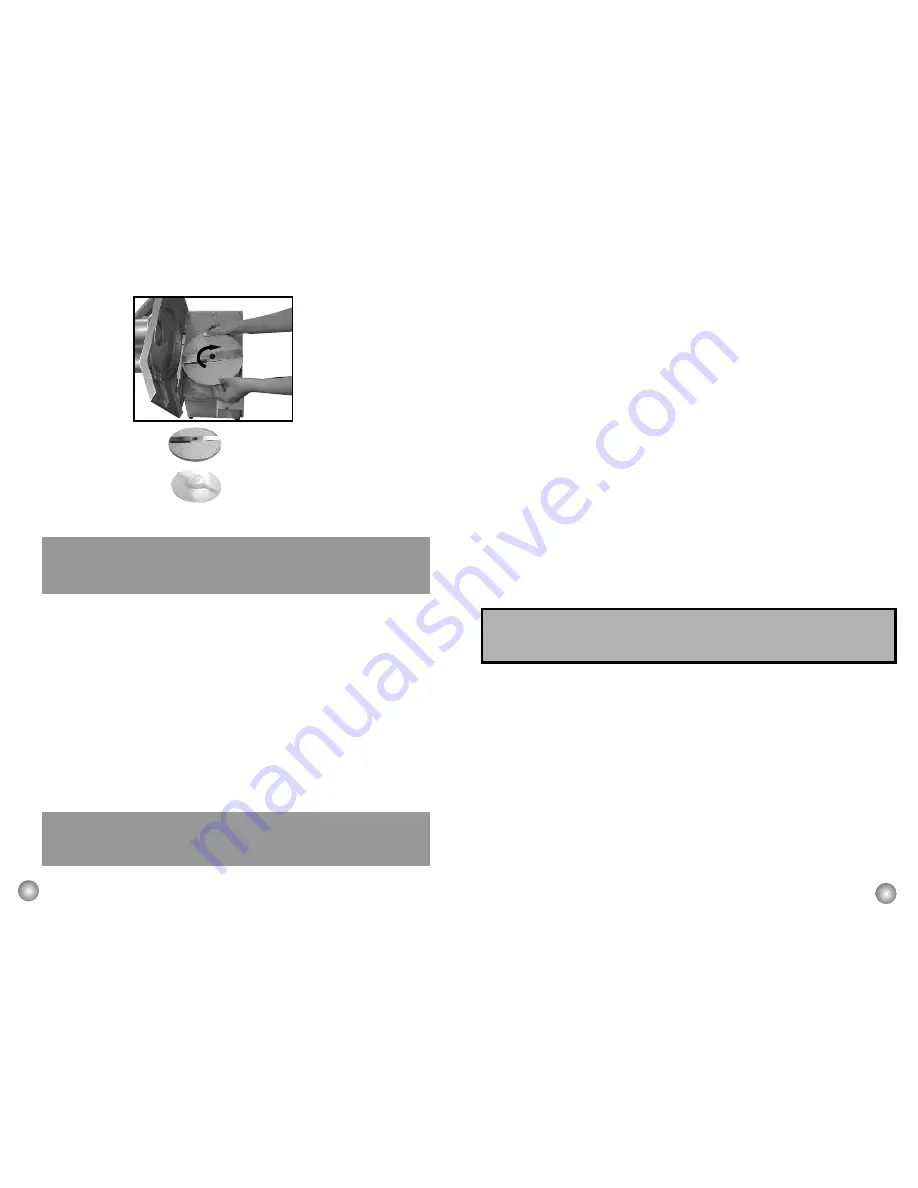

Picture - 07

Expeller Dish

Slicer Disc E5

3.3 Using a Slicer Disc and a Grille

IMPORTANT

The Expeller Dish shall always be on place , independently of the disc or

grille currently in use . Before to open the frame lid , be assured the disc is

completely still .

The grille shall be fitted in between the expeller dish and the disc , that will

have to be perfectly clean to fit perfectly .

Only Slicer disc shall be used : E10, Eh7.

Follows the instruction to place and remove the discs and the grille :

3.3.1 With the machine switched OFF and the disc still, move the frame lid

open/close trigger , placed below on the right side , as shown on the open/close

label - Picture - 06 stuck on the lid . With the frame lid open , be careful with the

Ram Feed Arm which has to be handled slowly .

IMPORTANT

The Slicer Dented Discs EH3 and EH7 are suitable to cut products with

skin and leaves ( example : tomatoes and lettuce ) .

4. General Safety Practices

The following safety instructions are addressed to both the operator of the

machine as well as the person in charge of maintenance. The machine has to be

delivered only in perfect conditions of use by the Distributor to the user. The user shall

operate the machine only after being well acquainted with the safety procedures

described in the present manual. READ THIS MANUAL WITH ATTENTION.

4.1 Basic Operation Practices

4.1.1 Dangerous parts

Some areas of the electric device have parts that are connected or have parts

connected to high voltage. These parts when touched may cause severe electrical

shocks or even be fatal.

Never touch manual commands such as switches, buttons, keys and knobs with

your hands wearing wet clothes and/or wet shoes. By not following these instructions

operator could be exposed to severe electrical shocks or even to a fatal situation.

IMPORTANT

If any item from the GENERAL SAFETY NOTIONS section is not applicable to

your product, please disregard it.

These substances attack the stainless steel due to the CHLORINE on its

composition, causing corrosion spots (pitting).

Even detergents used in domestic cleaning must not remain in contact with

the stainless steel longer than the necessary, being mandatory to remove it with

plain water and then dry the surface completely.

Use of abrasives:

Sponges or steel wool and carbon steel brushes, besides scratching the

surface and compromising the stainless steel protection, leave particles that rust

and react contaminating the stainless steel. That is why such products must not be

used for cleaning and sanitization. Scrapings made with sharp instruments or

similar must also be avoided.

Main substances that cause stainless steel corrosion:

Dust, grease, acid solutions such as vinegar, fruit juices, etc., saltern

solutions (brine), blood, detergents (except for the neutral ones), common steel

particles, residue of sponges or common steel wool, and also other abrasives.

Summary of Contents for PAIE

Page 2: ......