05

Picture - 03

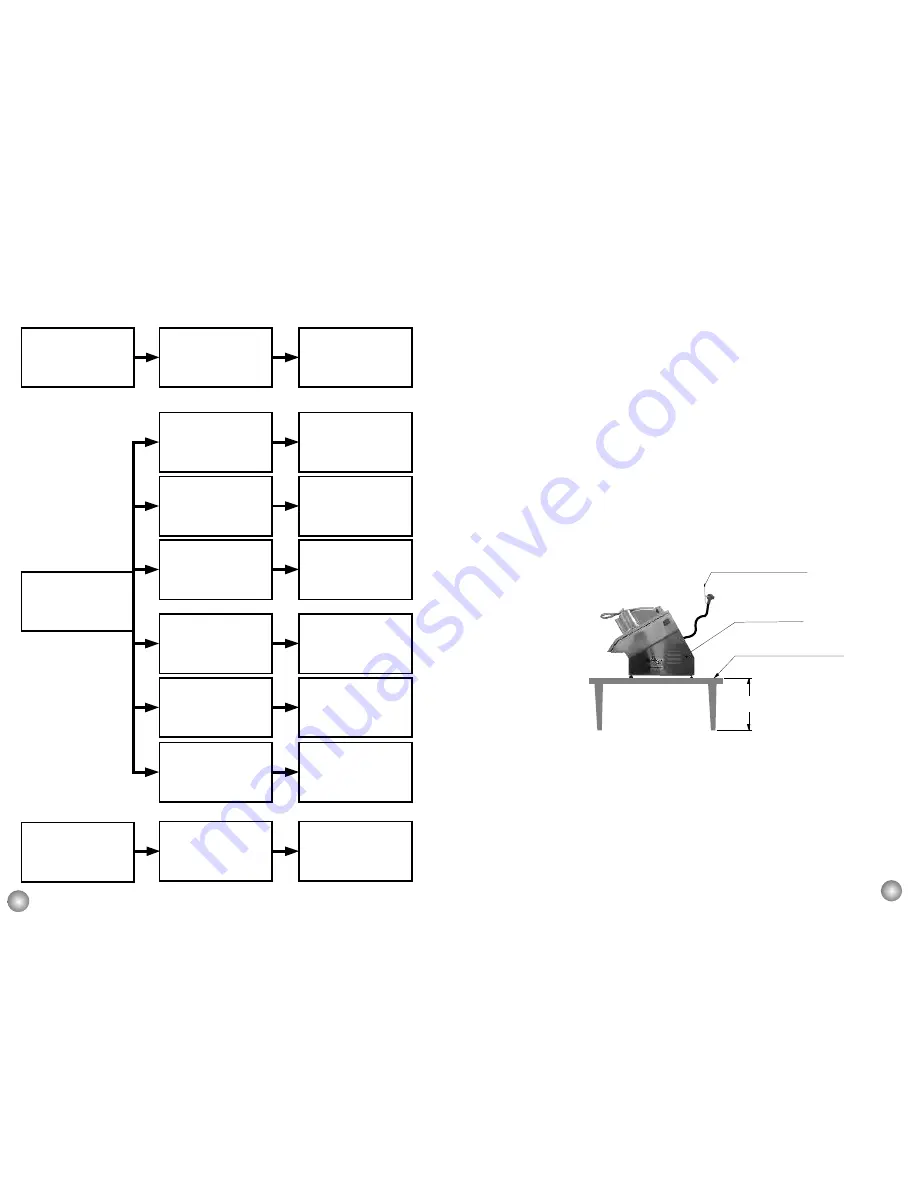

Cord With Grounding

Leveled working Surface

Motor Housing

Maximum height = 850mm

2. INSTALLATION AND PRE-OPERATION

2.1 Installation

The Food Processor should be placed on a leveled working surface ,

preferably 850 mm high above floor . Below the outlet, place a recipient to collect the

processed product .

Control the electricity source voltage , it shall be the same as the Food

Processor motor voltage, 110 or 220 V . The label stuck on the cord will give you the

right voltage.

The cord has a plug with two round pins and a grounding wire (earth wire) .

The three shall be well connected before to switch ON the machine .

2.2

Pre- Operation

Be sure the Food Processor is stable . Before to start operation wash the discs

and the grilles with hot water and neutral soap , rinse and dry before to replace them into

the machine .

2.3

Selecting the Discs and Grilles

To be supplied as optional a complete range of discs and grilles are at your

disposal , to process a wide vegetables and fruits products .

20

Problems

Causes

Solutions

* The cut product remains

inside the machine.

* The expeller dish is not in

place.

* Place the expeller dish, as

recommended at item 3,2

and 3,3l.

* The disc stops during

operation.

* Electric Failure.

* See if the machine cord

is plugged on its socket.

* Motor belts are sliding.

* T i g h t t h e b e l t i n

accordance with item 5,2l.

* The ram feed arm safety

device has a bad contact or

is out of order.

* Adust the safety device,

and check the electric

contacts.

* The frame lid safety device

has a bad contact.

* Call technical assistence.

* the ON/OFF switch has a

bad contact.

* Check the contacts.

* he plug or the cord has a

bad contact.

* Check the cord to find out

if there is an interruption,

and check the plug pins.

* The food Processor does

not start.

* Electricity shortage.

* Check electricity supply.

Summary of Contents for PAIE

Page 2: ......