5

6. MAINTENANCE

Maintenance must be considered a set of procedures

with the purpose to keep the equipment best operating

conditions, therefore increasing the equipment life and

safety.

Cleaning – check item 5 CLEANING

W

iring - Check all wires regarding deteriorate conditions as

well as all electric contacts (terminals) regarding tightening

and corrosion.

C

ontacts – ON/OFF switch, emergency button, reset button,

electronic circuits, etc., check the equipment in order to

assure that all components are correctly working and the

equipment operation is normal.

I

nstallation – make sure the installation followed item 3

instructions.

Life span: 50.000 cycles as per test standard.

1 – Each month check:

- Check the electrical installation

- Measure the voltage at the socket

- Measure the working current and match it with the

nominal current

- Check the tightening of all electric terminals to avoid bad

contacts

- Check electric motor shaft clearance

- Check the wiring for overeating , insulation failures and

mechanical damages.

- Lubricate the bearings once every two months. We

recommend the utilizaton of GBR Lithium MP2 Grease.

2 Each three month checks

- Check electrical components such as ON/OFF switch,

emergency button , reset button, electronic electric circuits ,

overeating, insulation failings, or mechanical damages

- Check bearings clearances

- Check retainers, O’rings, V’rings and other seals

Use Your QR Code Reader to access

more information regarding safety and

maintenance.

PROBLEMS

CAUSES

SOLUTIONS

- The equipment does not

switch on.

- Lack of Power;

- Problem with the internal or

external electric circuits.

- Check if there is electric power.

- Call Technical Assistance.

- Machine switch on but when

product touches the blade it

stops or runs slowly.

- Belt slipping on pulleys.

- Damaged Motor.

- Adjust the blade tension, see item 4.2.3;

- Call Technical Assistance.

- Smoke or burn smell.

- Problem with the internal or

external electric circuits.

- Call Technical Assistance.

- Blade breaks frequently.

- Dirty Blade or Wheel.

- Wheel Damaged.

- Clean,see the item 5 CLEANING.

- Call Technical Assistance.

- Damaged Cord.

- Problem during transportation.

- Call Technical Assistance.

- Unusual noises.

- Problems with bearings.

- Call Technical Assistance.

- Difficulties to cut the product.

- Dirty blade or wheels.

- Blade with wrong tension;

- Blade is not on wheels center;

- Blunt blade.

- Clean, see the item 5 CLEANING;

- Adjust the blade tension, see item 4.2.3;

- Call Technical Assistance.

- Change the Blade.

7. PROBLEM SOLUTIONS

Summary of Contents for SFL-282HD

Page 6: ...6 8 ELECTRICAL DIAGRAMS SFL 282 295HD 110 V 60 Hz ...

Page 7: ...7 SFL 282 295HD 220 V 60 Hz ...

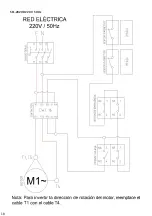

Page 8: ...8 SFL 282HD 220 V 50 Hz ...

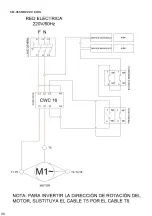

Page 9: ...9 SFL 315HD 220 V 50 Hz ...

Page 10: ...10 SFL 315HD 220 V 60 Hz ...

Page 11: ...11 SFL 315HD 110 V 60 Hz ...

Page 16: ...16 8 DIAGRAMAS ELECTRICOS SFL 282 295HD 110 V 60 Hz ...

Page 17: ...17 SFL 282 295HD 220 V 60 Hz ...

Page 18: ...18 SFL 282HD 220 V 50 Hz ...

Page 19: ...19 SFL 315HD 220 V 50 Hz ...

Page 20: ...20 SFL 315HD 220 V 60 Hz ...

Page 21: ...21 SFL 315HD 110 V 60 Hz ...