Rev. 10/19/11

3

AFVK-SP Series Valve Kit

Trouble Shooting Guide (AF-4000 Series)

AFVK-SP

– Manual ON/OFF switch, manual HI/LO flame adjustment & a ON, OFF transmitter

AFVK-SP-H/L

– Manual ON/OFF switch, solenoid for HI/LO & a ON, OFF, HI, LO transmitter

AFVK-SP-MH/L

– Manual ON/OFF switch, motor drive for variable flame adjustment & a ON, OFF, HI, LO

transmitter

Components that may be installed with Valve Kit:

Standard:

Optional:

SP1001

ON, OFF, ON/OFF/Continuous Pilot

AFVK-SP-PILOT/60

60” wire leads and pilot

SP1001 H/L

ON, OFF, HI, LOW, ON/OFF/ Continuous Pilot

tubing

AF-4000BP

Battery Pack

AF-4000ADP24

6 Volts DC Adapter

AF-4000MOD-1

Control Module (learns 3 transmitters)

In order to trouble shoot any product it is important to understand the basic operation

and functions of that product. The following information will assist you through this

process

.

General Lighting Information

Lighting Procedure:

Pushing the ON button sends a radio frequency signal to the module. This sends power to the pilot assembly and the

sparking begins. The gas valve will open, sending gas to the pilot. Sparking stops after the sensor recognizes the

flame and burner ignition is complete. ON/OFF/Continuous Pilot allows you to activate the continuous pilot feature

and allows the use of a standing pilot.

Control Module (AF-4000MOD-1) “Brain” of the system; has built in fault codes:

The module, inside the valve box, controls the operation of the valve kit. If module detects a problem, it will begin

emitting a series of audible beeps (fault codes). The audible beeps indicate a fault and will assist in locating the

problem.

Fault Codes

Ignition Safety – 1 beep every 1 second

Ignitor will not spark / Burner has not ignited within 60 seconds.

Check

•

Gas is ON; line is purged of air and no blockage in the

pilot and main lines.

•

Pilot assembly electrodes are clean, no soot build-up (clean

with steel wool if needed).

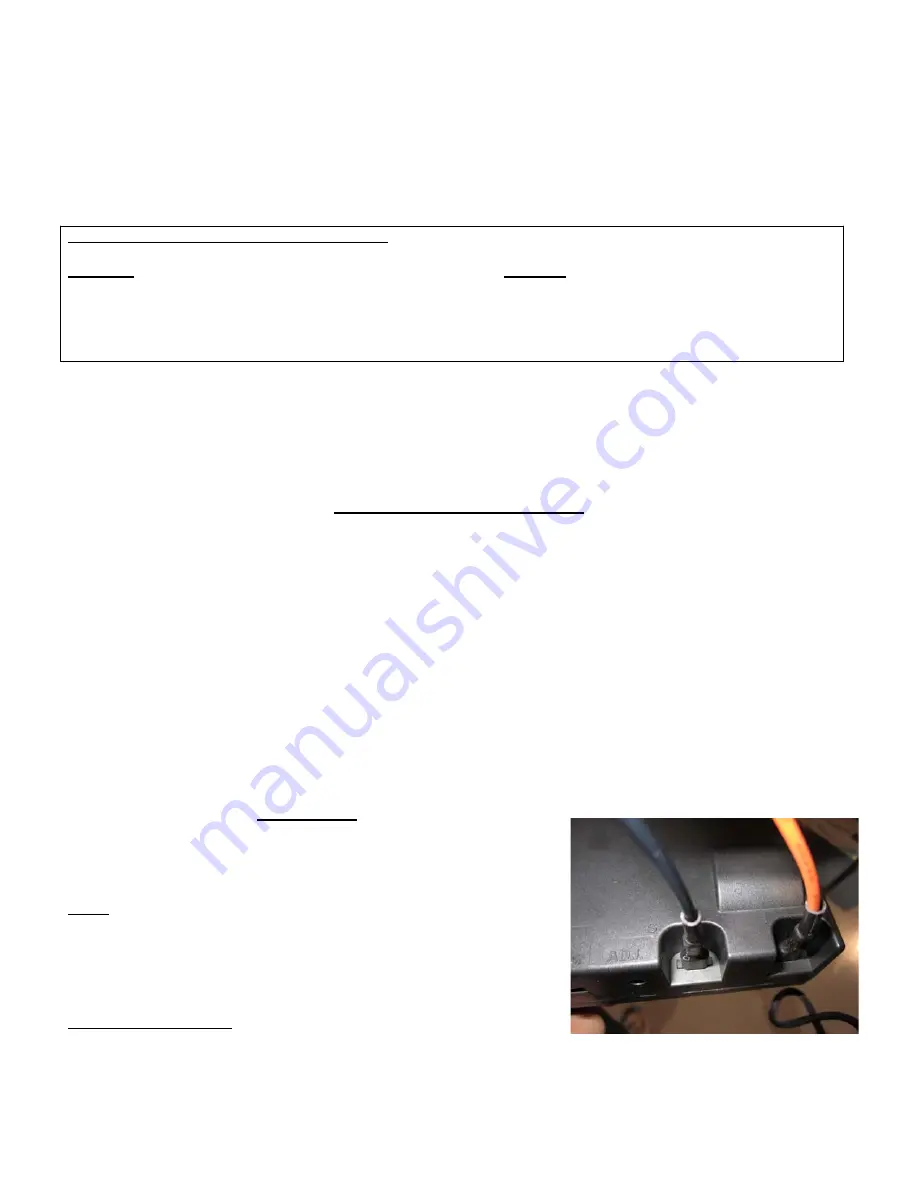

Check Wire Connections

•

Pilot wires –“I” (Ignitor) and “S” (Sensor) wires connected

Igniter

“I”

Sensor

“S”

Fig. 1

f i r e - p a r t s . c o m