Page 6

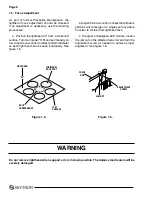

1-3. Preventive Maintenance Procedures

The following procedures should be done semi-

annually or sooner as needed.

a. Lighthead top cover should be removed and

any accumulation of dust or lint removed.

b. Check the focus drive mechanism for proper

operation and lubrication. Lubricate the drive

gears with lithium grease and all pivot points with

a lightweight oil as necessary.

c. All attaching hardware (screws, nuts, etc.)

should be physically checked for tightness. Any

missing hardware MUST be replaced.

WARNING

Apply LOC-TITE to any replacement

or loose vertical support tube attach-

ing screws.

d. Rotate the radial arm assemblies around the

ceiling mount to check the slip ring/brush block as-

semblies. With electrical power "ON", if the lights

become intermittent or go out, check and repair or

replace the brush block or slip ring as necessary.

e. Check the remaining slip ring/brush block

assemblies by raising, lowering, and rotating the

lighthead through its full range of motion. With

electrical power "ON", if the lights become inter-

mittent or go out, check and repair or replace the

appropriate brush block or slip ring as necessary.

f. Check all fixture rotation axes for proper ad-

justment. Adjust as necessary using applicable

adjustment procedures from the adjustment section

of this manual (Section 2).

SECTION I MAINTENANCE

1-1. General

To ensure proper operation and extend the life of

your SKYTRON surgical lighting fixture, the fol-

lowing preventive maintenance procedures are

recommended.

NOTE

All repairs should be made using autho-

rized SKYTRON replacement parts.

1-2. Daily Maintenance

Daily or between cases, the lighthead exterior

should be wiped down with a mild cleaning agent

which will not affect the painted or acrylic parts.

Do not apply or spray cleaning agents directly on

the lighthead.

CAUTION

Use of incompatible cleaning agents will

cause damage to the fixture. Avoid the

use of cleaning solutions which contain

high concentrations of alcohol, ethelene

glycol, phenol, iodophors, or glutaral-

dehyde based disinfectancts. Staining,

pitting, discoloration and diffuser crack-

ing may occur if these are used.

•Only dissinfectants and cleaners may be used that

are certified from the manufacturer for compatibility

with the following materials:

-- Polycarbonate (PC)

-- Polyvinylchloride (PVC)

-- Silicones

•Always consult with the manufacturer of the clean

-

ing agent for proper application and use. Always

spot test on an inconspicuous area before use.

•Avoid personal injury. Do not attempt to clean light

-

head unless power is turned off at wall control.

•Avoid using excessive amounts of spray cleaners.

Leakage of fluids into the interior of lighthead may

cause corrosion of electrical components.

Summary of Contents for AURORA LED 5 4000K

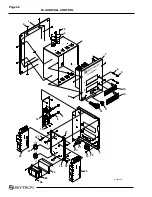

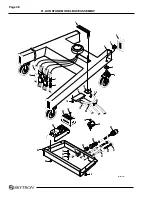

Page 1: ...REV 9 08 INSTALLATION INSTRUCTIONS LED SERIES SURGICAL LIGHTS...

Page 18: ...Page 16...

Page 20: ...Page 18...

Page 26: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 27: ...LED SERIES SURGICAL LIGHTS OPERATORS MANUAL TEC B 0002 REV0 1 09...

Page 47: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 48: ...PARTS CATALOG LED SERIES SURGICAL LIGHT TEC B 0009 REV3 3 10...

Page 54: ...Page 5 17 Stand Model Support Post Assembly page 40...

Page 65: ...Page 16 6 LED POD ASSEMBLY 57 010307 03mj 3 2 1 4 10 5 6 7 12 13 15 14 15 13 16 8 11 9...

Page 73: ...Page 24 10 LIGHTHEAD ASSEMBLY 1 2 6 7 8 9 11 13 14 12 10 5 3 4 57 031408 06mj...

Page 81: ...Page 32 13 TV LIGHTHEAD ASSEMBLY 1 3 4 5 6 7 8 9 10 11 12 15 17 18 13 16 14 2 5tv 081308 03...

Page 83: ...Page 34 14 WALL CONTROL ASSEMBLY 57 010307 04 1 5 6 9 10 3 2 7 8 4...

Page 85: ...Page 36 15 WALL CONTROL COMPONENTS 57 010307 05 1 2 3 4 5 6 12 13 14 7 8 9 10 11...

Page 91: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 92: ...MAINTENANCE MANUAL LED SERIES SURGICAL LIGHT 7 07...

Page 93: ......

Page 95: ...Page 2...

Page 110: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 111: ...REV 8 08 INSTALLATION INSTRUCTIONS LFS SERIES SURGICAL LIGHTS...

Page 133: ...Page 21...

Page 135: ...Page 23...

Page 138: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 139: ...LFS SERIES OWNERS MANUAL REV 6 08...

Page 140: ......

Page 142: ...Page 2...

Page 160: ...Page 20...

Page 170: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 171: ...INSTALLATION INSTRUCTIONS AUR SERIES SURGICAL LIGHTS TEC B 0006 REV1 8 09...

Page 188: ...Page 16 TYPICAL AURORA AUR LIGHT FIXTURE CONDUIT AND WIRING REQUIREMENTS...

Page 189: ...Page 17 TYPICAL WIRING DIAGRAM...

Page 190: ...Page 18 TYPICAL AURORA AURTV LIGHT FIXTURE CONDUIT AND WIRING REQUIREMENTS...

Page 191: ...Page 19 TYPICAL WIRING DIAGRAM...

Page 196: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 197: ...AUR SERIES SURGICAL LIGHTS OPERATORS MANUAL TEC B 0003 REV9 3 10...

Page 198: ......

Page 219: ......

Page 220: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 221: ...PARTS CATALOG AUR SERIES SURGICAL LIGHT TEC B 0004 REV6 6 10...

Page 222: ......

Page 274: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 275: ...AUR SERIES SURGICAL LIGHTS MAINTENANCE MANUAL TEC B 0007 REV1 1 10...

Page 276: ......

Page 278: ...Page 2...

Page 292: ...Page 16 TYPICAL WIRING DIAGRAM...

Page 293: ......

Page 294: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 295: ...TEC B 0008 REV3 3 10 OWNERS MANUAL HANDLE CAMERA SYSTEM...

Page 296: ......

Page 308: ...Page 12 PRECISION HD CAMERA SYSTEM...

Page 310: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...