Page 4

RECOMMENDED TOOL LIST

1 PIN PUNCH SET 1/8" - 3/8"

1 TEFLON TYPE SPRAY LUBRICANT (TRI-FLOW)

1 SET OF PHILLIPS SCREWDRIVERS

1 SET OF FLAT BLADE SCREWDRIVERS

1 DIGITAL LEVEL

1 METRIC, L-TYPE ALLEN WRENCH SET 1.5-8mm

1 PENCIL

1 TRUE RMS VOLTMETER

1 SET OF NON ABRASIVE CLEAN CLOTHS

1 MILD CLEANING AGENT, NON ALCOHOL

ATTENTION, CONSULT MANUAL FOR FURTHER INSTRUCTIONS.

INDICATES SPECIAL USER ATTENTION.

AC VOLTAGE

EQUIPMENT LABELS AND SPECIFICATIONS

FUSE TYPE 2 AMP, 250V, TIMELAG

2A

CLASS I, TYPE B EQUIPMENT- IPXO RATED.

CONTINUOUS OPERATION

TYPE B

EQUIPMENT

PERMISSIBLE ENVIRONMENTAL CONDITIONS

DURING TRANSPORT AND STORAGE (IN ORIGINAL PACKAGING MATERIALS)

• AMBIENT TEMPERATURE:

10° - 60° C (14° - 140° F)

• RELATIVE AIR MOISTURE:

10% - 85%, NO CONDENSATE BUILD-UP

• AIR PRESSURE: 500 hPa - 1060 hPa (14 in-Hg - 31 in-Hg)

DURING USE - FOR DRY LOCATIONS

• AMBIENT TEMPERATURE:

15° - 30° C (60° - 85° F)

• RELATIVE AIR MOISTURE:

30% - 60% NON CONDENSING

• AIR PRESSURE: 700hPa - 1060 hPa (20.7 in-Hg - 31.3 in-Hg)

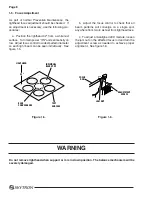

WARNING

This equipment is intended for use by healthcare professionals only. This equipment may cause

radio interference or may disrupt the operation of nearby equipment. It may be necesssary to

take mitigation measures, such as re-orienting or relocating the lighthead or shielding the

location.

Summary of Contents for AURORA LED 5 4000K

Page 1: ...REV 9 08 INSTALLATION INSTRUCTIONS LED SERIES SURGICAL LIGHTS...

Page 18: ...Page 16...

Page 20: ...Page 18...

Page 26: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 27: ...LED SERIES SURGICAL LIGHTS OPERATORS MANUAL TEC B 0002 REV0 1 09...

Page 47: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 48: ...PARTS CATALOG LED SERIES SURGICAL LIGHT TEC B 0009 REV3 3 10...

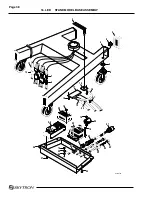

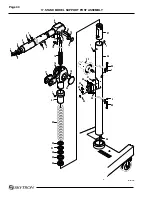

Page 54: ...Page 5 17 Stand Model Support Post Assembly page 40...

Page 65: ...Page 16 6 LED POD ASSEMBLY 57 010307 03mj 3 2 1 4 10 5 6 7 12 13 15 14 15 13 16 8 11 9...

Page 73: ...Page 24 10 LIGHTHEAD ASSEMBLY 1 2 6 7 8 9 11 13 14 12 10 5 3 4 57 031408 06mj...

Page 81: ...Page 32 13 TV LIGHTHEAD ASSEMBLY 1 3 4 5 6 7 8 9 10 11 12 15 17 18 13 16 14 2 5tv 081308 03...

Page 83: ...Page 34 14 WALL CONTROL ASSEMBLY 57 010307 04 1 5 6 9 10 3 2 7 8 4...

Page 85: ...Page 36 15 WALL CONTROL COMPONENTS 57 010307 05 1 2 3 4 5 6 12 13 14 7 8 9 10 11...

Page 91: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 92: ...MAINTENANCE MANUAL LED SERIES SURGICAL LIGHT 7 07...

Page 93: ......

Page 95: ...Page 2...

Page 110: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 111: ...REV 8 08 INSTALLATION INSTRUCTIONS LFS SERIES SURGICAL LIGHTS...

Page 133: ...Page 21...

Page 135: ...Page 23...

Page 138: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 139: ...LFS SERIES OWNERS MANUAL REV 6 08...

Page 140: ......

Page 142: ...Page 2...

Page 160: ...Page 20...

Page 170: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 171: ...INSTALLATION INSTRUCTIONS AUR SERIES SURGICAL LIGHTS TEC B 0006 REV1 8 09...

Page 188: ...Page 16 TYPICAL AURORA AUR LIGHT FIXTURE CONDUIT AND WIRING REQUIREMENTS...

Page 189: ...Page 17 TYPICAL WIRING DIAGRAM...

Page 190: ...Page 18 TYPICAL AURORA AURTV LIGHT FIXTURE CONDUIT AND WIRING REQUIREMENTS...

Page 191: ...Page 19 TYPICAL WIRING DIAGRAM...

Page 196: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...

Page 197: ...AUR SERIES SURGICAL LIGHTS OPERATORS MANUAL TEC B 0003 REV9 3 10...

Page 198: ......

Page 219: ......

Page 220: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 221: ...PARTS CATALOG AUR SERIES SURGICAL LIGHT TEC B 0004 REV6 6 10...

Page 222: ......

Page 274: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 275: ...AUR SERIES SURGICAL LIGHTS MAINTENANCE MANUAL TEC B 0007 REV1 1 10...

Page 276: ......

Page 278: ...Page 2...

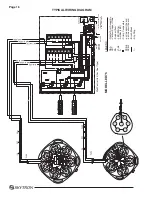

Page 292: ...Page 16 TYPICAL WIRING DIAGRAM...

Page 293: ......

Page 294: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 616 656 2900 FAX 616 656 2906...

Page 295: ...TEC B 0008 REV3 3 10 OWNERS MANUAL HANDLE CAMERA SYSTEM...

Page 296: ......

Page 308: ...Page 12 PRECISION HD CAMERA SYSTEM...

Page 310: ...5085 Corporate Exchange Blvd S E Grand Rapids MI 49512 1 616 656 2900 FAX 1 616 656 2906...