Page 9

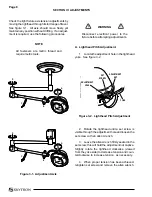

C. Vertical Travel

The vertical travel spring tension is set at the

factory (ceiling and wall mount models) and should

not need adjusting. However, if an adjustment is

necessary, use the following procedure. See fig-

ure 3-4.

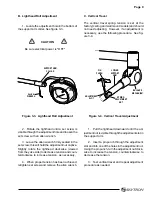

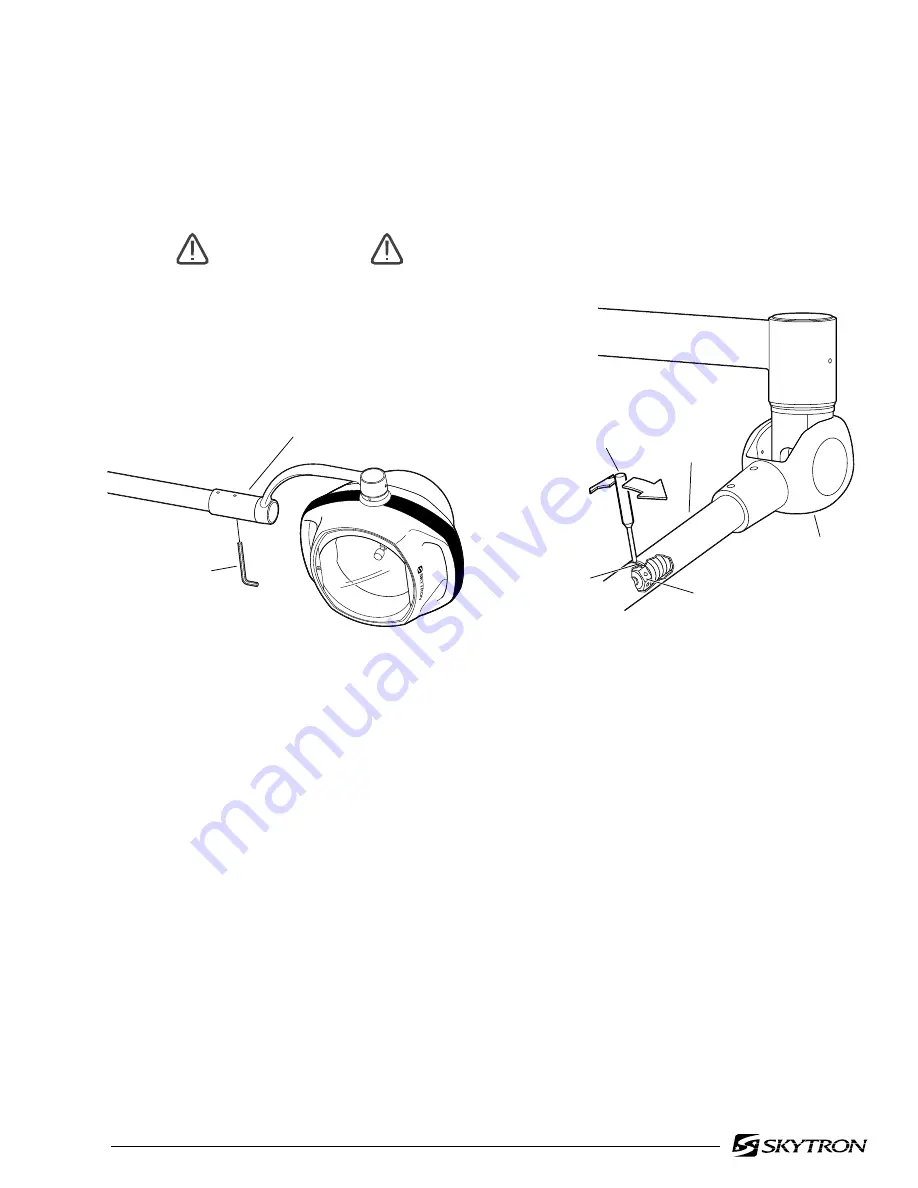

Figure 3-3. Lighthead Roll Adjustment

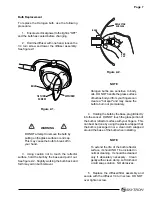

2. Rotate the lighthead until a set screw is

visable through the adjustment hole and loosen the

set screw with an allen wrench.

3. Leave the allen wrench firmly seated in the

set screw; this will hold the adjustment nut captive.

Slightly rotate the lighthead clockwise (viewed

from the yoke side) to decrease tension and coun-

terclockwise to increase tension, as necessary.

4. When proper tension has been achieved,

retighten set screw and remove the allen wrench.

B. Lighthead Roll Adjustment

1. Locate the adjustment hole in the bottom of

the support arm collar. See figure 3-3.

CAUTION

Be sure electrical power is "OFF"

SUPPORT ARM

COLLAR

ALLEN

WRENCH

BALANCE

MECHANISM

SPRING

ADJUSTMENT

NUT

LOWER

SUPPORT

ARM

PIN

PUNCH

ADJUSTMENT

SLOT

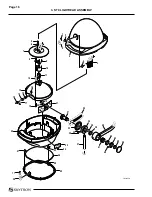

Figure 3-4. Vertical Travel Adjustment

1. Pull the lighthead downward until the ad-

justment nut is visible through the adjustment slot in

the support arm.

2. Insert a pin punch through the adjustment

slot and into one of the holes in the adjustment nut.

Using the pin punch, turn the adjustment nut clock-

wise to increase the tension, counterclockwise to

decrease the tension.

3. Test vertical travel and repeat adjustment

procedure as needed.