Page 10

Bulb Voltage

The ST9 series is equipped with a voltage compen-

sation device that will deliver the necessary bulb

output with a voltage range of between 110VAC

and 120VAC. Routine bulb voltage adjustments

are not necessary if supply voltage falls within this

range.

ADJUSTMENT

NUT

ADJUSTMENT

HOLE

LOWER

SUPPORT ARM

UPPER

RADIAL ARM

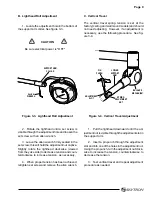

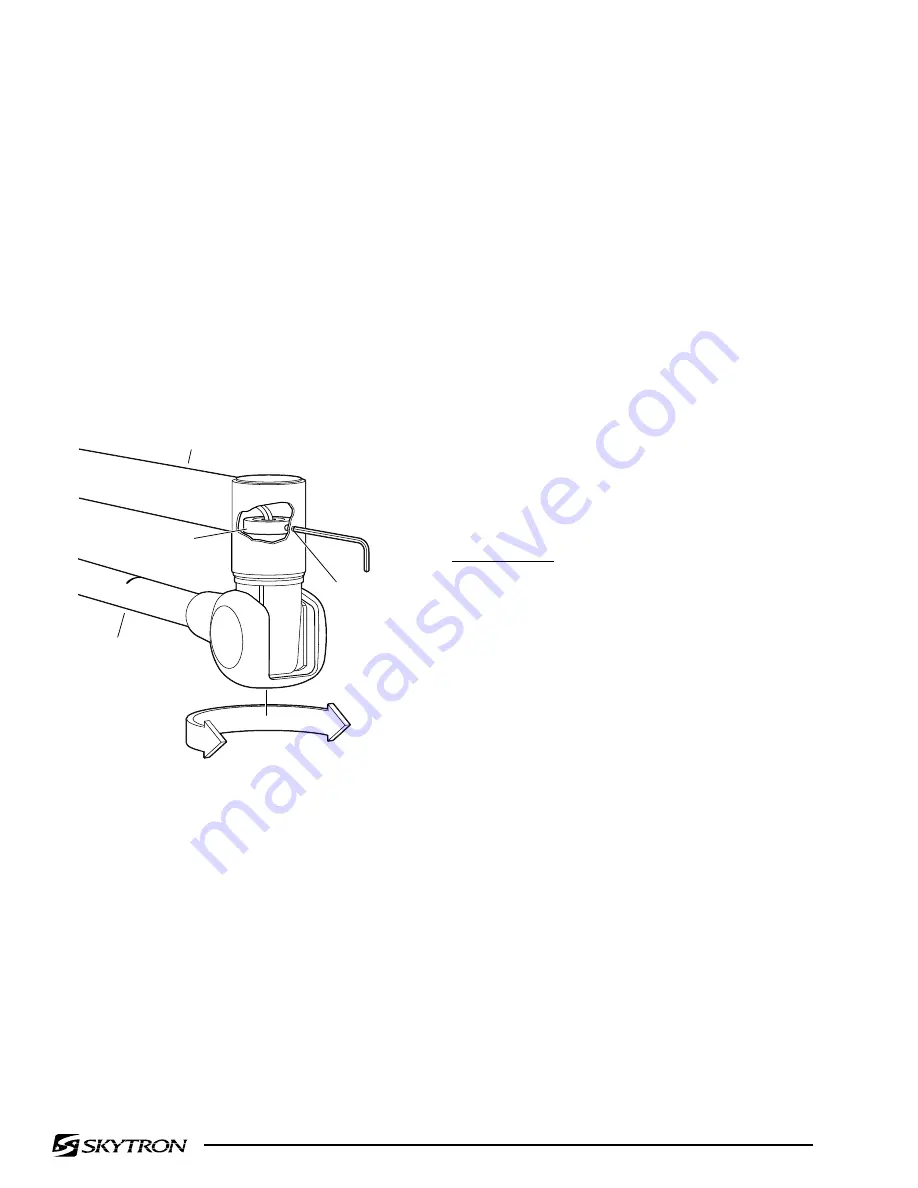

D. Lighthead Horizontal Rotation

Adjustment

The lighthead should maintain its position without

drifting, yet move freely. Normally this adjustment

is correct from the factory and does not change. If

the lighthead drifts, the most probable cause is a

non-plumb mounting hub.

Recheck the fixture mounting hub to make sure

that it is plumb. In most cases this will solve any

drifting problems. If not, use the following adjust-

ment procedure to adjust the bearing preload. See

figure 3-5.

Figure 3-5. Horizontal Rotation Adjustment

1. Locate the adjustment hole and rotate the

lower support arm until a set screw is visible in the

adjustment nut. Loosen the set screw with an allen

wrench.

2. Leave the allen wrench firmly seated in the

set screw; this will hold the adjustment nut captive.

Carefully rotate the lower support arm slightly.

Move the arm counterclockwise (viewed from the

bottom) to decrease tension and clockwise to

increase the tension.

3. Tighten the set screw, remove the allen

wrench and recheck the tension adjustment.