15

motor

parts

list

ITEM DESCRIPTION

PART # QTY

1*

GEAR CASE

07458

1

2

LIP SEAL

07367

1

3

NEEDLE BEARING

UH3220

1

4

SPINDLE SEAL

04807

1

5

SPINDLE SEAL

04805

1

6

EXTERNAL RETAINING RING

UH4036

1

7

BALL BEARING

UH3072

1

8

MOTOR SPINDLE

07368

1

9

INTERNAL RETAINING RING

UH4157

1

10

KEY

07467

1

11

GEAR

07448

1

12

EXTERNAL RETAINING RING

UH4020

1

13

NEEDLE BEARING

UH3216

1

14

THRUST WASHER

07426

1

15

GEARSHAFT

07427

1

16

GEAR

07428

1

17

EXTERNAL RETAINING RING

UH4018

1

18

NEEDLE BEARING

UH3030

1

19

NEEDLE BEARING

UH3018

1

20

OVERLOAD LABEL

07374

1

21

PINION SHAFT

07439

1

22

KEY

07438

1

23

DUAL GEAR

07440

1

24

NEEDLE BEARING

UH3015

3

25

BALL BEARING

UH3021

2

26

PINION SHAFT

07432

1

27

KEY

07433

1

28

DUAL GEAR

07434

1

29

GEARSHAFT

07446

1

30

GEAR

07444

1

31

WOODRUFF KEY

04564

1

32

HELICAL INPUT GEAR

04582

1

33

SHIFT FORK

07357

2

34

SHORT SHIFT PIN

07356

1

35

SHIFT LEVER I

07450

1

36

ROLL PIN

UH4205

2

37

SPRING

04591

2

38

SHIFT DRIVE PIN

04524

2

39

M5 LOCK WASHER

UH2056

2

40

M5 X 35 SHCS

UH0558

2

41

SHIFT LEVER LABEL

04514

2

42

M3 X 5 CRPHMS

UH0300

4

43

LONG SHIFT PIN

07343

1

44

SHIFT LEVER II

07424

1

45

SNAP BUSHING

07441

3

ITEM DESCRIPTION

PART # QTY

46

SPECIAL WASHER

07443

1

47

M5 X 12 DOWEL PIN

UH4200

1

48

GEARBOX GASKET

04593

1

49

GEAR CASE COVER

07442

1

50

M8 LOCK WASHER

UH2083

4

51

M8 X 40 SHCS

UH0820

4

52

SPEED RANGE LABEL

07422

1

53

BEARING HOUSING

07445

1

54

M6 X 20 SHCS

UH0640 1

55

M5 X 16 DOWEL PIN

UH4201

1

56

FIELD HOUSING

054074

1

57

FIELD CASE COVER

054061

1

58

WIRING DIAGRAM LABEL

054062

1

59

INTAKE LOUVER

054070

2

60

BRUSH HOLDER

04551

2

61

MOTOR BRUSH

04549

2

62

BRUSH CAP

04552

2

63

FIELD SLEEVE INSULATOR

04558

1

64

FIELD INSULATOR SCREW

04557

4

65

FIELD, 120V

04555

1

FIELD, 220V

04556

66

M4 LOCK WASHER

UH2044 2

67

M4 X 60 SHCS

UH0438

2

68

FAN SHROUD

054079

1

69

UPPER ARMATURE WASHER

04560

1

70

BALL BEARING

UH3021

1

71

ARMATURE, 120V

04553

1

ARMATURE, 220V

04554

72 KEY

07435 1

73

BALL BEARING

UH3039

1

74

CIRCUIT BOARD OVERLOAD

054067

1

75

PIPE HANDLE HOLE PLUG

054011

1

76

MOTOR TAG, 120V

054057

1

77

DRIVE SCREW

UH1002

2

78

CIRCUIT BOARD INSULATOR

054012

2

79

M3 X 10 CRPHTCS

UH0312

8

80

M4 LOCK WASHER

UH2044 4

81

M4 X 8 CRPHMS

UH0400

4

82

M6 X 12 FPSSS

UH0612 2

83

M5 X 16 CROHMS

UH0528

4

84

LED SOCKET

054054

1

85

LED INDICATOR

054085

1

86

INTERNAL RETAINING RING

UH4142

1

87

M3 X 8 CRPHMS

UH0306

1

88

M3 LOCK WASHER

UH2036

1

Rev. D

*Note: Order 07459 for complete Gear Box assembly

Summary of Contents for 17985

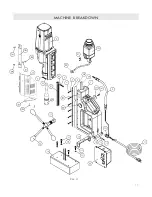

Page 11: ...machine breakdown 11 Rev D...

Page 14: ...motor breakdown Rev D 14...