13

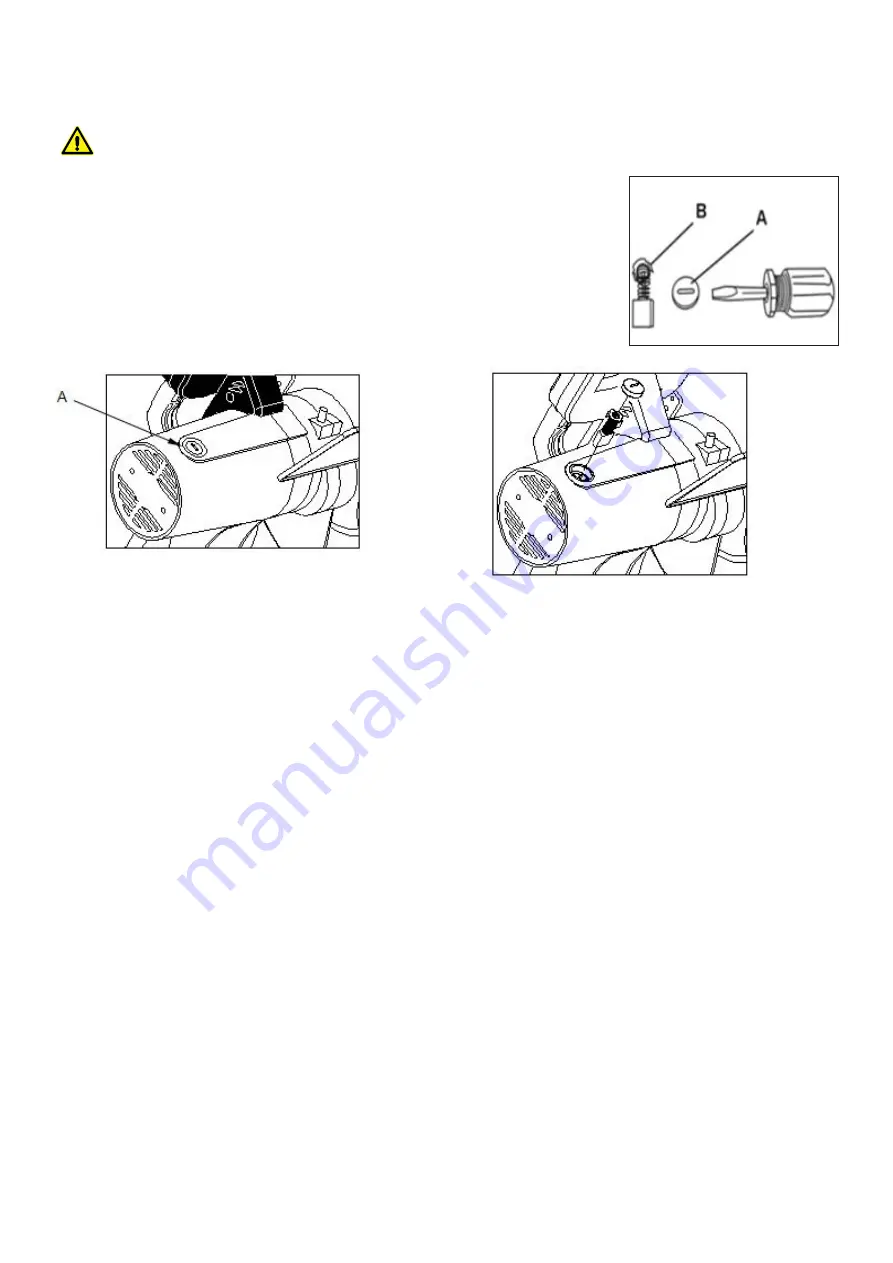

REPLACING CARBON BRUSHES

CAUTION:

Turn off the switch and disconnect plug from power supply before

checking.

Check brushes regularly, if worn down to 1/4” (6mm), replace

brushes. Carbon brushes should be clean and slide freely in

holder. Carbon brushes should be replaced in pairs. Use a

flat blade screwdriver to remove the brush cap (A)

(Note: This cap is spring-loaded by the brush assembly.),

take out the worn carbon brush (B), insert new carbon brush

and secure the brush holder cap.

*Refer to Imagery.

MAINTENANCE AND LUBRICATION

DANGER: Never put injury from lubricants on the blade while it is spinning

Keep the tool clean. Remove accumulated shavings from working parts.

Make sure that the tool operates properly, Periodically check screws and bolts for tightness.

Feed oil at the oiling points once a month for extending machine service life (machine oil is suit-

able for the saw). Oiling points are:

•

Rotary part of shaft

•

Rotary part of vise

•

Slide way of vise

Lubrication

All the motor bearings in this tool are lubricated with a sufficient amount of high grade lubricant for

the life of the unit under normal operation conditions, therefore no further lubrication is required.

Lubrication as Required:

Up Stop Screws: Light machine oil or aerosol will penetrate from ends and junction points. Ex-

posed surfaces are lubricated with automotive type oil.

Central pivot of guard: Use light household oil (3 in 1 oil) on metal-to-metal guard contact areas

as required for smooth, quiet operation. Avoid excess oil, to which cutting debris will cling and fire

hazard from sparks could be caused.

Fig. 20

Fig. 21

Fig. 22

Summary of Contents for 72905361120

Page 15: ...15 PARTS DIAGRAM...

Page 21: ...21...