16

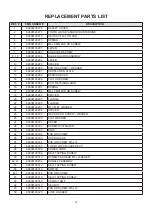

REPLACEMENT PARTS LIST

REF. #

FEIN ORDER #

DESCRIPTION

1

69908120276

SAFETY COVER

2

69908120277

TOOTH LOCK WASHER COUNTERSINK

3

69908120278

HEX SOC FLAT HD SCR

4

69908120279

SPRING

5

69908120280

M4 x 8MM PAN HD SCREW

6

69908120281

LEVER

7

69908120282

SHOULDER SCREW

8, 18

69908120453

BLADE GUARD ASSEMBLY

9

69908120284

LEVER

10

69908120285

SPACER

11

69908120286

PAN HD SCREW + WASHER

12

69908120287

PROTECTION PLATE

13

69908120288

BEARING BASS

14

69908120289

FLAT HD SCREW

15

69908120290

EXTL RETAINING RING

16

69908120291

SPRING

17

69908120292

M4 x 8MM PAN HD SCREW

19

69908120294

SPACER

20

69908120295

FLANGE

22

69908120296

FLANGE

23

69908120297

M10 FLAT WASHER

24

69908120298

SPACER

25

69908120299

HEX SOC HD SCREW +WASHER

26

69908120300

FLAT WASHER

27

69908120301

COVER

28

69908120302

SCREW W/ WASHER

33

69908120303

STOP

34

69908120304

PAN HD SCREW

35

69908120305

CORD GUARD

36

69908120306

PAN HD SCREW M5 x 12

37

69908120307

TOOTH LOCK WASHER EXT'

38

69908120308

POWER CORD

39

69908120309

SELF TAPPING SCREW

40

69908120310

SCREW PAN HEAD M5 + WASHER

42, 47

69908120452

HANDLE ASSEMBLY

43

69908120312

SELF TAPPING SCREW

44

69908120313

SWITCH

44.1

69908120314

PAN HD SCREW

45

69908120315

SELF TAPPING SCREW

46

69908120316

CORD CLAMP

48

69908120318

HEX NUT

49

69908120319

PAN HD SCREW M5 x 12

50

69908120320

LOCK WASHER

Summary of Contents for 72905361120

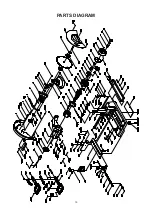

Page 15: ...15 PARTS DIAGRAM...

Page 21: ...21...