5

operator if proper precautions are taken.

b) When blade is binding or when interrupting a cut for any reason, release the trigger

and hold the saw motionless in the material until the blade comes to a complete

stop. Never attempt to remove the saw from the work or remove the saw blade from

the work piece while in motion or kickback may occur.

Investigate and take corrective

actions to eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, center the saw blade in the cut and check

that saw teeth are not engaged into the material.

If saw blade is binding, it may walk up

or kickback from the workpiece as the saw is restarted.

d) Support long material lengths to minimize the risk of blade pinching and kickback.

Long length materials tend to sag under their own weight. Supports must be placed

under the material on both sides near the line of cut and near the edge of the material.

e) Do not use dull or damaged blades.

Unsharpened or improperly mounted blades

produce narrow cuts causing excessive friction, blade binding and kickback.

f) Blade depth and bevel adjusting locking levers must be tight and secure before

making cut.

If blade adjustment shifts while cutting, it may cause binding and kickback.

Guard Safety Instructions

a) Check guards for proper closing before each use. Do not operate the saw if guards don’t

move freely and close instantly. Never clamp or tie the guards into the open position.

If saw is accidentally dropped, guards may be bent.

b) Check the operation of the guards springs. If the guards and the spring are not operating

properly, they must be serviced before use.

The guards may operate sluggishly due to

damaged parts, gummy deposits, or a build-up of debris.

c) When the saw blade is lowered, both guards separate to perform cut.

d) Always observe that the guards are covering the blade before leaving the saw.

Be aware

of the time it takes for the blade to stop after switch is released.

Additional Safety Instructions

•

Use the vice to secure and support the workpiece. Holding the work by hand or against your

body leaves it unstable and may lead to loss of control.

•

Keep your body positioned to either side of the blade, but not in line with the saw blade.

KICKBACK could cause material to jump backwards (see Causes and Operator Prevention of

KICKBACK).

•

Always make sure nothing interferes with the movement of the blade guards.

•

Accessories must be rated for at least the speed recommended on the tool warning label.

Wheels and other accessories running over rated speed can fly apart and injure. Accessory

ratings must always be above tool speed as shown on tool nameplate.

•

Always make sure the saw is clean before using.

•

Stop using this saw and have it properly serviced if any unusual noise or abnormal operation

occcurs.

•

Always be sure all components are mounted properly and securely before using tool.

•

Always handle the saw blade with care when mounting or removing it or when removing the

diamond knockout.

•

Always wait until the motor has reached full speed before starting a cut.

Summary of Contents for 72905361120

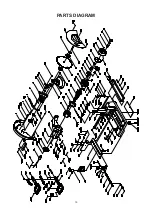

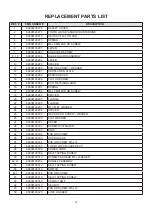

Page 15: ...15 PARTS DIAGRAM...

Page 21: ...21...