13

en

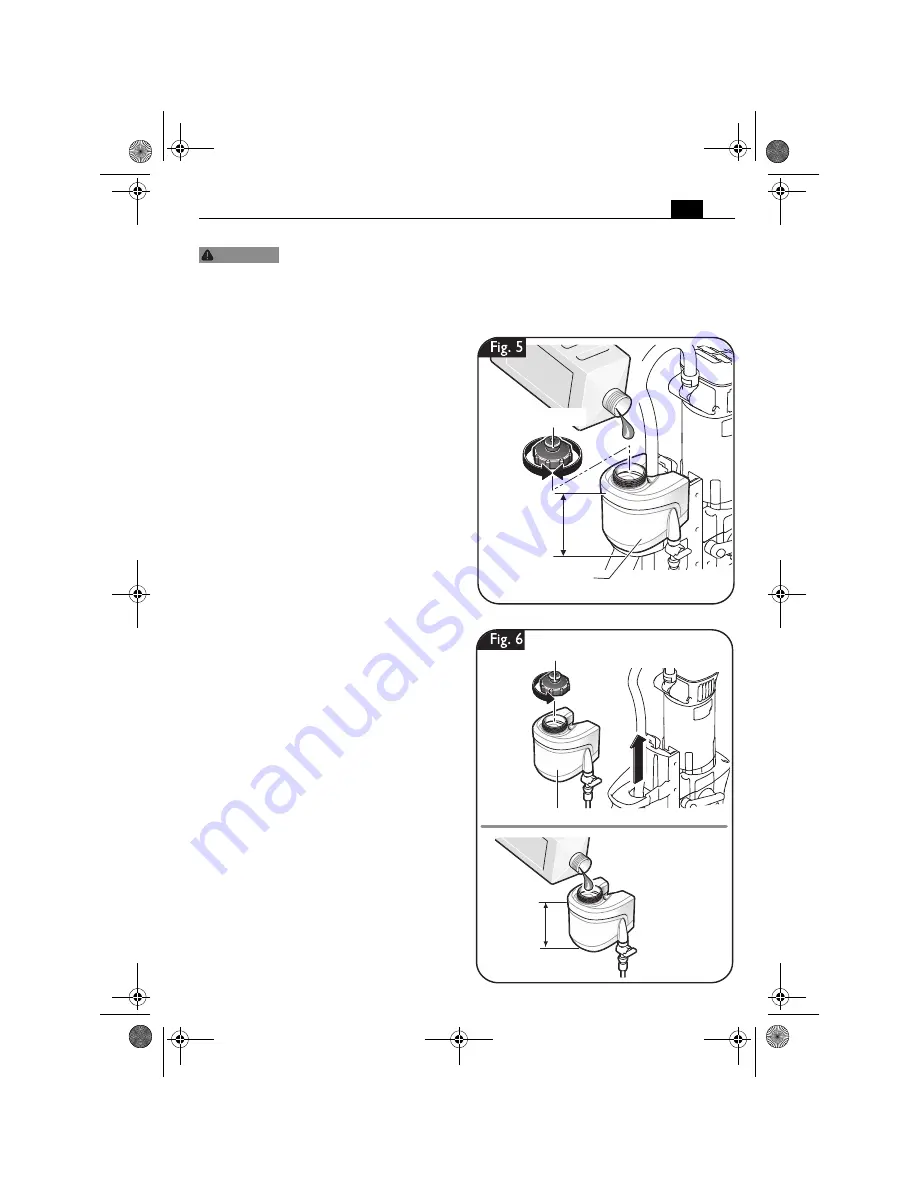

Filling the coolant container.

Prevent the flow of liquid along the cable into the socket outlet or into the core

drill unit, as this can lead to electric shock. Tie a bow in the cable near the plug,

so that any liquid can drip off.

Do not use the magnetic base drill unit if the cooling lubricant system is defective. Check for

proper seal against leaks and for cracks in the hoses. Prevent liquids from entering or penetrat-

ing electrical components.

Filling the mounted coolant container

(figure 5)

Unscrew the cap from the coolant container.

Fill in pump-feedable cooling lubricant, e.g.

Slugger cutting oil.

Screw the cap onto the coolant container

again.

Filling the dismounted coolant container

(figure 6)

Pull the empty coolant container out of the

drill stand housing of the magnetic core drill.

Unscrew the cap from the coolant container.

Fill in pump-feedable cooling lubricant, e.g.

Slugger cutting oil.

Screw the cap onto the coolant container

again.

Insert the filled coolant container into the

holder on the drill stand housing intended for

this purpose.

WARNING

Coolant container

Upper closing cap

max. 500 ml max. 17 fl. OZ.

max. 500 ml max. 17 fl. OZ.

Coolant container

Upper closing cap

OBJ_BUCH-0000000130-002.book Page 13 Monday, November 18, 2013 10:38 AM