15

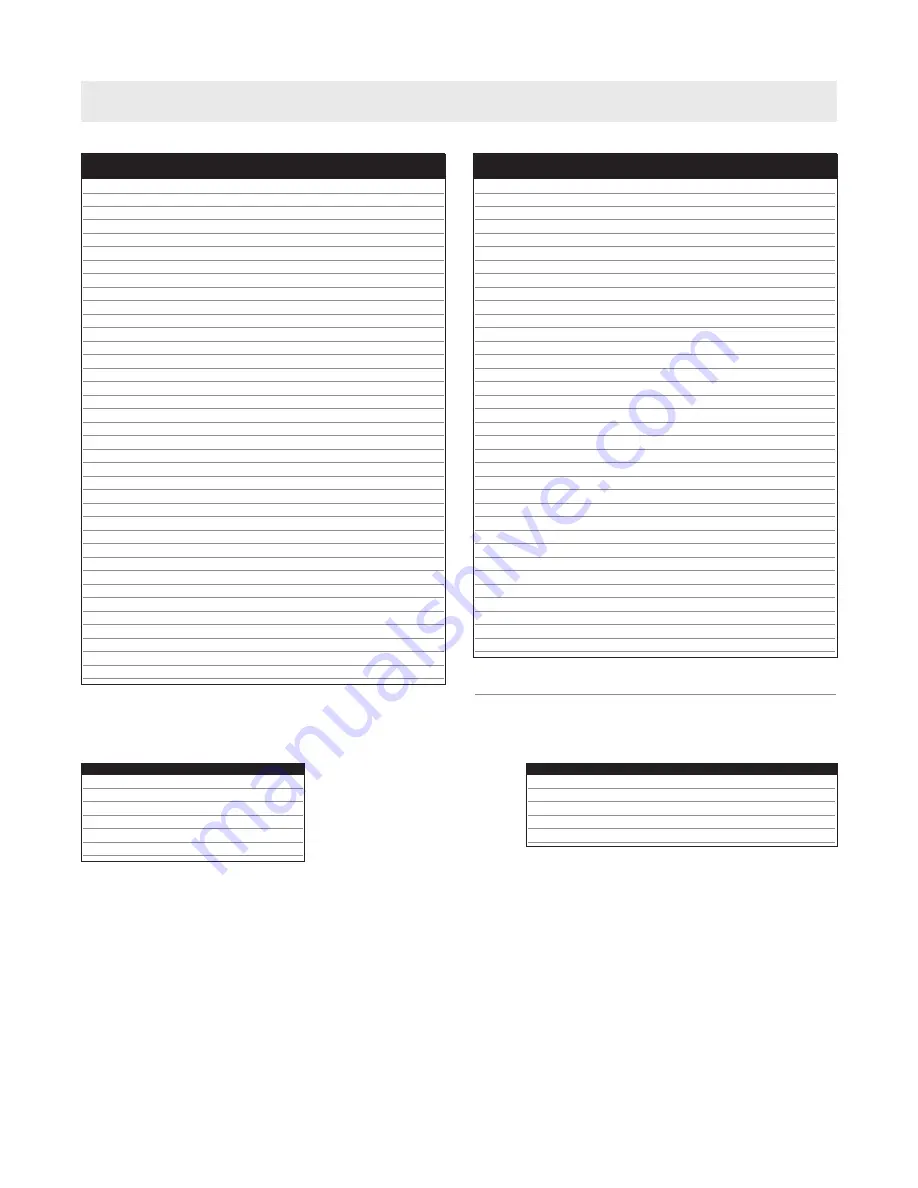

slugger

cutters

cutter

decimal

1"

depth

cut

2"

depth

cut

3"

depth

cut

diameter

equivalent

part

#

part

#

part

#

7/16

.4375

S4375

SL437

NA

1/2

.5000

S5000

SL500

NA

13MM

.5118

S5118

SL511

NA

14MM

.5512

S5512

SL551

NA

9/16

.5625

S5625

SL562

NA

15MM

.5906

S5906

SL590

NA

5/8

.6250

S6250

SL625

NA

16MM

.6299

S6299

SL629

NA

17MM

.6693

S6693

SL669

NA

11/16

.6875

S6875

SL687

NA

18MM

.7087

S7087

SL708

NA

19MM

.7480

S7480

SL748

NA

3/4

.7500

S7500

SL750

7500S

20MM

.7874

S7874

SL787

*7874S

13/16

.8125

S8125

SL812

8125S

21MM

.8268

S8268

SL826

*8268S

22MM

.8661

S8661

SL866

*8661S

7/8

.8750

S8750

SL875

8750S

23MM

.9055

S9055

SL905

*9055S

15/16

.9375

S9375

SL937

9375S

24MM

.9449

S9449

SL944

*9449S

25MM

.9843

S9843

SL984

*9843S

1

1.000

S1000

SL100

1000S

26MM

1.023

S1023

SL102

*1023S

1-1/16

1.062

S1062

SL106

1062S

27MM

1.063

S1063

SL107

*1063S

28MM

1.102

S1102

SL110

*1102S

1-1/8

1.125

S1125

SL112

1125S

29MM

1.141

S1141

SL114

*1141S

30MM

1.181

S1181

SL118

*1181S

1-3/16

1.187

S1187

SL119

1187S

31MM

1.220

S1220

SL122

*1220S

1-1/4

1.250

S1250

SL125

1250S

32MM

1.259

S1259

SL126

*1259S

33MM

1.299

S1299

SL129

*1299S

1-5/16

1.312

S1312

SL131

1312S

34MM

1.338

S1338

SL133

*1338S

cutter

decimal

1"

depth

cut

2"

depth

cut

3"

depth

cut

diameter

equivalent

part

#

part

#

part

#

1-3/8

1.375

S1375

SL137

1375S

35MM

1.377

S1377

SL138

*1377S

36MM

1.417

S1417

SL141

*1417S

1-7/16

1.437

S1437

SL143

1437S

37MM

1.456

S1456

SL145

*1456S

38MM

1.496

S1496

SL149

*1496S

1-1/2

1.500

S1500

SL150

1500S

39MM

1.535

S1535

SL153

*1535S

1-9/16

1.562

S1562

SL156

1562S

40MM

1.574

S1574

SL157

*1574S

41MM

1.614

S1614

SL161

*1614S

1-5/8

1.625

S1625

SL162

1625S

42MM

1.654

S1654

SL165

*1654S

1-11/16 1.687

S1687

SL168

1687S

43MM

1.692

S1692

SL169

*1692S

44MM

1.732

S1732

SL173

*1732S

1-3/4

1.750

S1750

SL175

1750S

45MM

1.771

S1771

SL177

*1771S

46MM

1.811

S1811

SL180

*1811S

1-13/16 1.812

S1812

SL181

1812S

47MM

1.850

S1850

SL185

*1850S

1-7/8

1.875

S1875

SL187

1875S

48MM

1.889

S1889

SL188

*1889S

49MM

1.929

S1929

SL192

*1929S

1-15/16 1.937

S1937

SL193

1937S

50MM

1.968

S1968

SL196

*1968S

2

2.000

S2000

SL200

2000S

51MM

2.007

S2007

SL201

*2007S

52MM

2.047

S2047

SL204

2047S

2-1/16

2.062

S2062

SL206

2062S

2-1/8

2.125

S2125-.75S

SL212-.75S

2125S-.75S

2-3/16

2.187

S2187-.75S

SL218-.75S

2187S-.75S

2-1/4

2.250

S2250-.75S

SL225-.75S

2250S-.75S

2-5/16

2.312

S2312-.75S

SL231-.75S

2312S-.75S

2-3/8

2.375

S2375-.75S

SL237-.75S

2375S-.75S

description

part

#

PINT

10206W

QUART

10207W

GALLON

10208W

5-GALLON

10209W

55-GALLONS

10210W

CUTTING PASTE

10205

coolant

and

cutting

paste

pilot

fits

cutter

sizes

part

#

1" DEPTH OF CUT / 1/2" DIAMETER AND SMALLER

16001

2" DEPTH OF CUT / 1/2" DIAMETER AND SMALLER

16002

1" DEPTH OF CUT / 9/16" DIAMETER AND LARGER

16003

2" DEPTH OF CUT / 9/16" DIAMETER AND LARGER

16004

ALL STANDARD 3" DEPTH OF CUT

16005

*

denotes

non

-

stock

cutters

.

consult

jancy

engineering

for

deliVery

.

note

: 3-

inch

depth

-

of

-

cut

slugger

cutters

are

not

aVailable

below

3/4"

diameter

.

slugger

cutter

pilot

pins

(

for

cutters

listed

aboVe

)