Remove all contents from packaging and inspect to ensure no damage was incurred during shipping. Your Magforce pack-

age should also include the following:

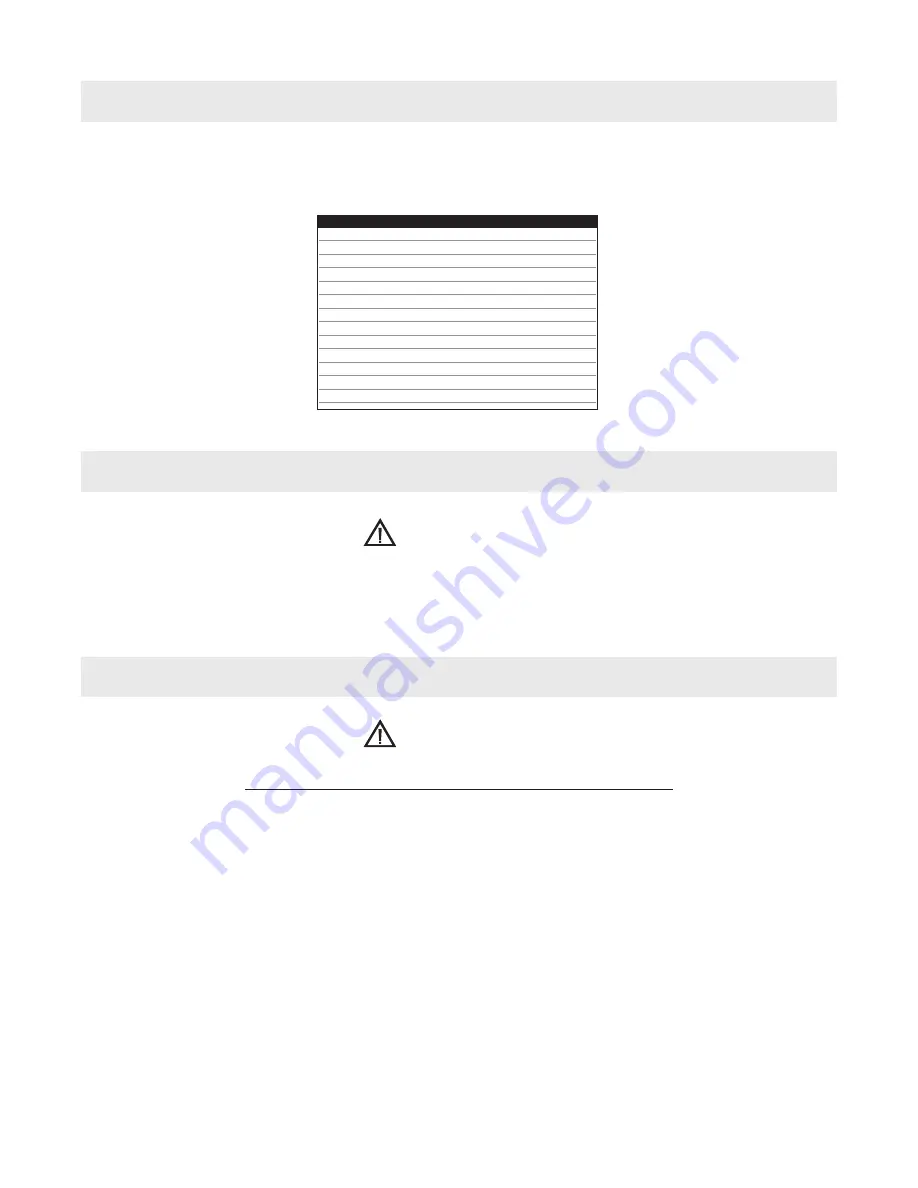

operating

instructions

(

before

you

begin

)

description

part

#

qty

OPERATOR’S MANUAL

LIT107A

1

WARNING CORD LABEL

06951

1

WARRANTY CARD

0070342

1

MAGNET NOTICE WARNING

0108D0C

1

3/16" PILOT, 1" DEPTH CUT

16001

1

3/16" PILOT, 2" DEPTH CUT

16002

1

1/4" PILOT, 1" DEPTH CUT

16003

1

1/4" PILOT, 2" DEPTH CUT

16004

1

SSS 10MM - 1.5 x 8MM FLAT POINT 70545

2

3MM HEx KEY

70586

1

5MM T-HANDLE WRENCH

70589

1

SAFETY STRAP

06798

1

SPOKE HANDLE ASSEMBLY

06316RS

1

getting

started

what

you

should

know

before

you

drill

CAUTION!

always

disconnect

magforce

from

power

source

before

making

adjustments

.

Assemble spoke handle assembly #06316RS to pinion feed shaft #06206 using screw which is attached to center of

drive handle.

NOTE:

Handle can be mounted on right or left side of machine.

WARNING!

smart

magnet

function

will

strobe

magnet

lamp

to

indicate

insufficient

magnetic

adhesion

.

smart magnet no longer interrupts motor function!

1. Type of material to be drilled, Brinnell or Rockwell hardness, material thickness and position should all be

determined to ensure proper selection of Slugger cutting tools, RPM, coolant and drilling time.

2. Remove any excessive mill scale or rust from surface to be drilled.

3. Material that has been flame cut may have become heat-treated and therefore difficult to drill. Avoid drilling

near such areas whenever possible.

4. Drilling with the Magforce in horizontal positions requires a special lubrication for Slugger cutters.

Consult Jancy Engineering for details.

5.

Do not use Slugger drilling machines on surfaces or materials being welded.

Doing so can damage the machine’s electrical components.

7