Page 3

DO

Clean and rinse your pump after each use with Fimco Tank

Neutralizer

Winterize your pump or sprayer by rinsing, draining and

running RV Antifreeze through it before storing for the winter.

Use clean water for your spray mixture

Store inside a building when not in use.

DON’T

Use to pump bleach.

Use to pump petroleum products such as diesel fuel,

gasoline or kerosene

Leave your pump sit with spray mixture in it for extended

periods

Use dirty or unfiltered water for spraying

Troubleshooting the Pump:

Motor does not run:

Check for loose wiring connection(s).

Make sure the 'ON/OFF' switch in the lead wire assembly

is in the 'ON' position. "I" is the 'ON' position and 'O' is

the 'OFF' position.

Check for defective pressure switch. Make sure you are

connected to a good 12 volt power source. Make sure

any on/off switches are in the 'on' position. Remove the

cap to the pressure switch. Pull both red wires off of their

terminals, and touch the two ends together. If your pump

runs when you do this, your pressure switch will need to

be replaced.

Check the fuse.

Check for low voltage at the power supply.

Pump does not prime:

Check for air leaks in supply line.

Check for debris in the check valve assembly.

Check for defective check valve.

Check for clogged strainer/filter.

Check for cracks in the pump housing.

Check for empty product supply.

Low Pressure/Low Flow:

Check for leaks in the discharge line.

Check for restriction in the discharge line.

Check for debris in nozzle orifice.

Check for clogged strainer.

Check for proper voltage—try another 12

-

volt battery.

Pulsating flow (surging):

Low flow may cause pump to surge.

Spray wand is adjusted for a small or fine spray pattern.

Slightly open bypass (if applicable) to overcome.

If needed, pressure switch may need to be adjusted—

adjust a quarter turn at a time clockwise until surging

stops.

Check for defective pressure switch.

Check for leaks in the discharge line.

Check for restriction in the discharge line.

Check for debris in nozzle orifice.

Discharge hose may be too long.

Check for clogged strainer.

Motor continues to run after discharge is shut off:

Check for empty product supply.

Check for open bypass valve. (if equipped)

Check for low voltage.

Check for leak in discharge line.

Check for defective pressure switch.

System has leaks.

Fuse blows:

Excessive voltage.

Improper adjustment of pressure switch.

Damaged or defective wiring harness.

Half

-

moon & counterweight are sticking.

Defective pressure switch.

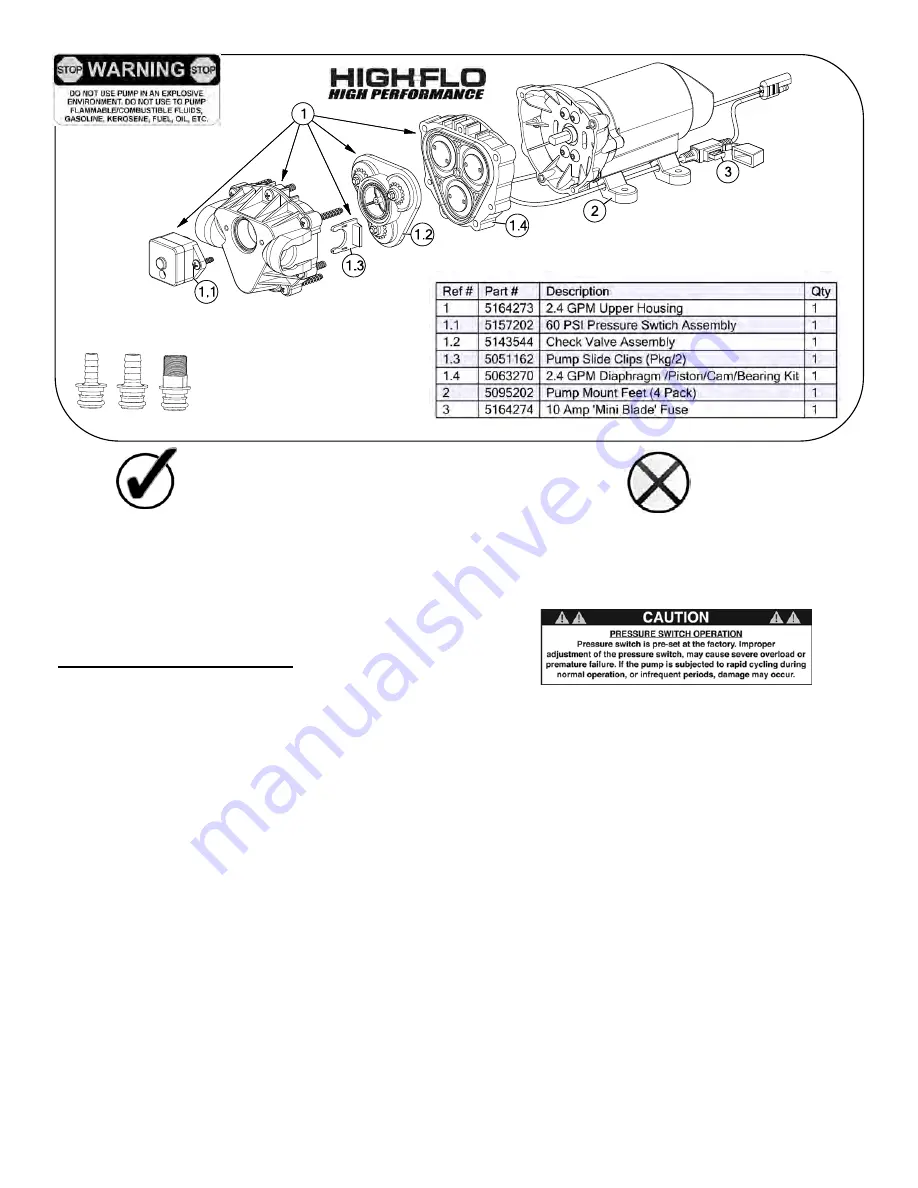

Pump Model: 5281371

2.4 GPM, 60 PSI

Available Replacement Parts

Replacement Pump: 5151087

Includes:

1/2” MNPT Port Kit Fitting

#5168832

1/2” Hose Barb Port Kit Fitting

#5168833

3/8” Hose Barb Port Kit Fitting

#5168836