•

Extended fault ride through capabilities (to

support reliable power generation during grid

faults) - depending on inverter configuration

•

Compliant with a wide range of international

grids

•

Adapted to local requirements and conditions via

grid code setting

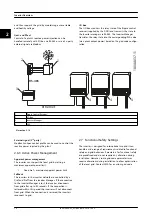

2.3.1 System Overview

The MLX system draws on the advantages of both string

inverters and central inverters, making it highly applicable

in many commercial and utility scale plants.

The MLX system consists of the MLX inverter itself, a DC

string combiner and the Inverter Manager.

The communication network of an MLX system is divided

into 2 Ethernet networks; Plant network and inverter

network. The plant network is the communication interface

to the MLX plant and may be shared by several Inverter

Managers as well as other IT equipment, while the inverter

network is solely used for MLX inverters. The plant network

must have a DHCP server (router) as the Inverter Manager

requires automatic IP assignment. It is recommended to

use professional grade routers and switches. The Inverter

Manager provides:

•

Control of up to 42 MLX inverters

•

Single point of access for each (up to) 2.5 MVA

plant for simple plant network deployment

•

Easy commissioning and service of the plant

using the Local Commissioning and Service (LCS)

tool

•

Safe upload to data warehouse services, and

control of all local requirements and settings

from the DNO

•

Open source Modbus TCP communication

protocol using SunSpec Alliance profile via

Ethernet both for monitoring and control, making

it easy to integrate in e.g. SCADA systems

•

Grid management interface through the optional

I/O box for PLA and reactive power commands

•

Easy integration of meteorological data using an

RS-485 SunSpec Alliance compliant weather

station

Inverter Overview

6

L00410648-02_02 / Rev. date: 2014-10-03

2

2